Biologically inspired silk fi broin grafted polyacrylonitrile fi ltration membrane prepared in Zn Cl2 aqueous solution

Jingng Li,Shuwen Li,Xiohui Wng,Fn Fn,Kongyin Zho,*,Junfu Wei,Linhu Zhng,Dunwn Zhu,*

a State Key Laboratory of Separation Membranes and Membrane Processes,Tianjin Polytechnic University,Tianjin 300387,China

b Tianjin Key Laboratory of Biomedical Materials,Institute of Biomedical Engineering,Chinese Academy of Medical Sciences&Peking Union Medical College,Tianjin 300192,China

Key words:Biologically inspired membrane Silk grafted polyacrylonitrile Zn Cl2 aqueous solution Narrow pore size distribution p H-Sensitivity Anti-fouling

ABSTRACT In this study,biologically inspired silk fi broin grafted polyacrylonitrile(SF-g-PAN)fi ltration membrane was prepared using Zn Cl2 aqueous solution as solvent,avoiding the use of organic solvents.Phase inversion occurred w hen Zn2+and Cl?ions gradually diffused into w ater,creating a well-connected ion channel network and the SF-g-PAN fi ltration membrane was obtained.The membranes were observed by SEM and 3Dultra-depth microscope.The hydrophilic property,pore size distribution and dye rejection of the membrane were investigated.Results showed that the membrane has no fi nger hole formation because Zn Cl2 aqueous solution hasa lower curing rate parameter compared with organic solvents.SF-g-PAN membrane possessed good anti-fouling properties and p H sensitivity.The pore size distribution of the SF-g-PAN membrane was 0.25–1.04 nm.The rejection of direct yellow 27(Mw=662.6)and amaranth(Mw=604.5)was 96.51%and 30.63%,with the fl ux of 72.32 Lm?2 h?1 and 73.83 Lm?2 h?1 respectively at 0.1 MPa.The SF-g-PAN membrane has a w ide range of applications prospect in fine separation,dye desalination,waste water treatment and biomedical fields.

Membrane separation is one of the most promising technologies in w ater treatment,desalination and biomedical fields[1–3].At present,the main method of preparing porous membranes is phase inversion.In the phase transformation process,the polymer solution is immersed in the non-solvent,and the phase separation occurs through the rapid diffusion exchange between the solvent and the non-solvent at the membrane interface.However,traditional membranes have many disadvantages such as membrane fouling,lack of response,and the difficulty to obtain narrow distributed pores[4].

Many methods have been used to prepare homoporous membranes to improve the separation ef fi ciency[5–8].Peinemannet al.[7]prepared homoporous membrane by non-solvent induced phase inversion of block copolymers.Wanget al.[8]prepared homoporous membranes from the blended amphiphilic block copolymers.But these methods are complex and cost much,andcannot produce large quantities of membranes.

In this case,the emergence of aquaporins(AQPs)provides inspiration for the design of high permeability and high selectivity Artificial membrane.Due to the presence of AQPs,natural biological membranes often exhibit excellent transport performance[9].AQPs has high permeability and can effectively intercept other ions and molecules.In order to reproduce the excellent transport performance of AQPs outside the cells,the scientists conducted a lot of research in recent years[10–12].Many kinds of inorganic materials were utilized to construct efficient w ater channels within membranes[13,14].Biet al.[15]prepared a novel thin fi lm nanocomposite membrane by interfacial polymerization method with the incorporation of graphene quantum dots.Due to the formation of Artificial w ater channel in polyamide layer,the pure w ater fl ux of membrane is greatly improved.The Artificial w ater channel is of great signi fi cance to explore the structure and transport mechanism of w ater channel.

Polyacrylonitrile(PAN)was w idely used in textiles and membranes[16].In order to improve the moisture absorption performance of PAN fiber,the homogeneous grafting of PAN onto silk fi broin(SF)was investigated.The slow diffusion of zinc chloride in coagulation bath results in dense fibers[17].SF is composed of three amino acids,glycine(45%),alanine(30%)and serine(12%).Amino acid residues endow SF with hydrophilicity and p H sensitivity[18].However,no literature was reported about the use of SF-g-PAN as fi ltration membrane[19].

In this paper,inspired by the structure and transport mechanism of AQPs,Zn Cl2aqueous solution was used as solvent to obtain a casting solution by homogeneous grafting of PAN onto the SF without pore forming agent.Then SF-g-PAN fi ltration membrane was fabricated by putting the casting solution into a w ater coagulation bath.Phase inversion occurred w hen Zn2+and Cl?ions gradually diffused into w ater,creating a well-connected ion channel network.The microphase separation of SF and PAN also forms a channel at the interface.Therefore,the obtained SF-g-PAN membrane has a narrow pore size distribution,high permeability and high selectivity,which can solve the contradiction between the membrane permeability and selectivity.The anti-fouling property,pore size distribution,dye rejection and p H-responsive property of the membrane were investigated.

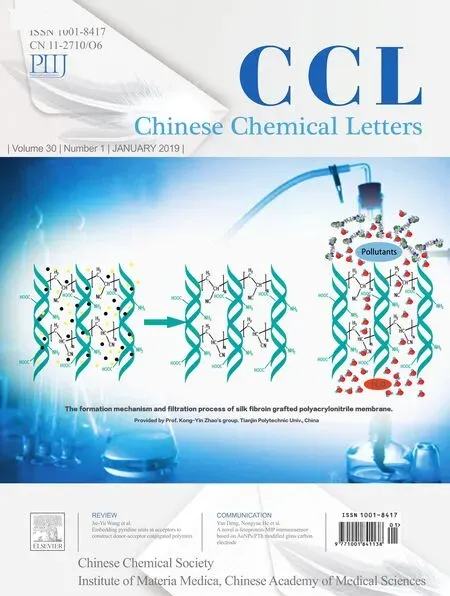

Fig.1 show s the formation and fi ltration mechanism of SF-g-PAN membrane.Phase inversion occurred w hen Zn2+and Cl?ions gradually diffused into w ater and many microporous were formed.The microphase inversion structure appeared between PANand SF.Then SF-g-PAN fi ltration membrane with narrow pore size distribution was obtained.The mechanism of the microphase inversion can be investigated in detail through multi-scale computer simulation.

Fig.S1(Supporting information)show s the preparation process of SF-g-PAN membrane.In a fl ask containing 52.2 m L 60 w t%Zn Cl2aqueous solution 3.5 g SF was dissolved at 55?C to obtain a homogenous solution.When the temperature was dow n to 26?C,10 m L AN and 0.8 m L 10 w t%(NH4)2S2O8was added.After 3 min,1 m L 10 w t%NaHSO3was added and the reaction was performed for 30 min under stirring.The homogenous SF-g-PAN solution was degassed and 3–6 g of the solution was poured on a clean fl at glass and unrolled by a glass rod w inding copper w ire at both ends(the diameter of the copper w ire was 0.40 mm).The glass was immediately immersed in deionized w ater at room temperature for 2 h.The SF-g-PAN fi ltration membrane was obtained after washing rudimental ions with deionized w ater.

Fig.S2(Supp orting information)show s the schematic diagram and d igital photo of the homemade cross-fl owequip ment.BSA aqueous solution(0.5 g/L)was used to investigate the anti-fouling p rop erty of the membrane.Amaranth and direct yellow 27 aqueous solutions(30 mg/L)were used to research the rejection property of the membrane.The concentrations of BSA or dye solution in feed and permeate solutions were measured by a UV spectrophotometer(UV-1100).The fl ux(J,L m?2h?1)and the rejection(R,%)were calculated by follow ing equations[20]:

w here Visthe permeate volume(L),Aisthe membrane area(m2),t is the time(h),Cpand Cfare the BSA or dye concentrations of permeate and feed solution,respectively.

The pure w ater fl ux(PWF)of SF-g-PAN fi ltration membrane was determined at 0.1 MPa and denoted as Jw1(L m?2h?1).Then,the feed solution was sw itched to BSAsolution for 30 min,and the fl ux of BSA solution was denoted as JB1.The process was repeated for four times.The anti-fouling property of the membrane was determined by the fl ux recovery rate(FRR)[20]:

w here Jwiis the PWF of i time.

Fig.2 shows the morphologies of SF-g-PAN fi ltration membrane.The SF-g-PAN fi ltration membrane was w hite and opaque and the thickness was 0.342 mm.From Fig.2b it is found that the wet membrane surface exhibited some well-distributed undulating peaks and valleys,which were caused by the different phaseinversion rates on different positions of the casting solution.The surface SEM image also approved the rough structure of the membrane surface.The cross-section SEM image of the membranes displays a dense structure without any fi ngerlike holes,which is different from most traditional polymeric membranes formed by a phase-inversion process[21].

Fig.2.Morphologies of SF-g-PAN fi ltration membrane.(a)Digital photo.(b)Surface 3D ultra-depth microscope image.(c)Surface and(d)cross-section SEM images.

Fig.1.The formation mechanism(a)and fi ltration process of SF-g-PAN membrane(b).

Fig.3.Antifouling and hydrophilic propertiesof SF-g-PAN membrane.(a)Alternating fi ltration fl ux between pure water and BSAsolution.(b)Dynamic water contact angle.

Fig.3 show s the antifouling and hydrophilic properties of SF-g-PAN membrane.The SF-g-PAN membrane exhibits excellent protein anti-fouling property.The FRR1was 96.6%.After three consecutive BSA fi ltrations,the FRR3still reached 93.5%without any washing operation.When a w ater droplet(1 m L)contacted the membrane surface,it spread out quickly and the contact angle was 28?,and it changed to 22?after 150 s(Fig.3b).

To determine the permeate size cut-off of the SF-g-PAN membranes prepared in this study,rigid dyes were used as probes[22].Different molecular weight dyes vary in molecular size.The larger the molecular weight is,the larger the corresponding molecular size.Fig.4a show s the fl ux and rejection rate of SF-g-PAN membrane using seven different molecular weight dyes as feed solutions at 0.1 MPa.The molecular weight and absorption peak w avelength of the seven dyes are showed in Table S1(Supporting information).The stable fl ux of all these seven dyes is above 80 L m?2h?1.The rejection rate for the dyes with a molecular weight greater than 660 was above 95%.However,the rejection for the dyes with a molecular weight below 600 was less than 30%.This indicates that SF-g-PAN fi ltration membrane pore size distribution is narrow,which can be finely separated.There isa high rejection rate for organic compounds with a molecular weight greater than 660,while the rejection rate for organic compounds with a molecular weight less than 600 is very low.The membrane can be applied to fine separation of drugs and biological samples[23].

Fig.4b show s the fl ux and rejection rate of brilliant blue solution under different operating pressure of SF-g-PAN membrane.The fl ux of the membrane is as high as 140 L m?2h-1at 0.3 MPa,but the rejection rate of brilliant blue is still close to 100%.The membrane has excellent performance both at lower operating pressures and higher operating pressures.

Fig.4c show sthe poresdistribution of SF-g-PANmembrane.The membrane had a narrow pore size distribution(0.25–1.04 nm)and the average pore size was 0.55 nm.This value is consistent with the permeate size cut-off of the SF-g-PAN membranes.SF-g-PAN membrane is expected to finely separate the samples with very similar molecular weight,although the mechanism of forming the narrow-distributed pores needs further investigation.The capability of the SF-g-PAN fi ltration membrane to separate small molecules predominantly by size could open new applications in the biotechnology and food industries.From Fig.4d,it is found that w hen the p H of direct yellow 27 solution alternately sw itched at 3.0 and 9.0,the fl ux repeatedly occurred at 101.5?1.62 and 78.9?1.17 L m?2h-1,and the rejection occurred at 83.5%?0.74%and 95.8%?0.43%,respectively.SF-g-PAN membrane exhibited good p H sensitivity,which was caused by the ionization of amino acid residues in SFat different p H values[18].

Inspired by the structure and transport mechanism of AQPs,SF-g-PAN fi ltration membrane was prepared without using any organic solvent and pore-forming agent.SF-g-PAN membrane exhibited anti-fouling properties and p H sensitivity.The rejection rate for the dyes with a molecular weight greater than 660 was above 95%,while the rejection rate for the dyes with a molecular weight below 600 was less than 30%,indicating that the SF-g-PAN fi ltration membrane possesses a narrow pore size distribution.The pore size distribution of SF-g-PAN membrane is about 0.25–1.04 nm.The pure w ater fl ux can reach 80 Lm?2h?1at 0.1 MPa.The membrane is promising for practical applications in fine separation,dye desalination,waste w ater treatment and biomedical fields.

[23_TD DIFF]Acknow ledgm ents

The research is supported by the National Natural Science Foundation of China(Nos.51678409,1708407,21476172),Tianjin Science Technology Research Funds of China(Nos.16JCZDJC37500,15JCZDJC38300),Program for Innovative Research Team in University of Tianjin(No.TD13-5042),and Science Foundation for the Youth Teachers of Peking Union Medical College(No.2014ZLGC0754).

Appendix A.Supplem entary data

Supplementary materialrelated to thisarticlecan befound,in the online version,at doi:https://doi.org/10.1016/j.cclet.2018.07.016.

Chinese Chemical Letters2019年1期

Chinese Chemical Letters2019年1期

- Chinese Chemical Letters的其它文章

- Information for authors

- A one-pot protocol for copper-mediated azide–alkyne cycloaddition using alkenyl tri fl ate precursors

- One-pot synthesis of tetrahydroindoles via a copper catalyzed N-alkynation/[4+2]cycloaddition cascade

- Gram-scale preparation of dialkylideneacetones through Ca(OH)2-catalyzed Claisen-Schmidt condensation in dilute aqueous EtOH

- Tetra-phthalimide end-fused bi fl uorenylidene:Synthesis and characterization

- Water bridges are essential to neonicotinoids:Insights from synthesis,bioassay and molecular modelling studies