Research on the Evaluation System of Epoxy Asphalt Steel Deck Pavement Distress Condition

Hui Zhang, Yingtao Li, Xinxin Fu and Youqiang Pan

(1.College of Aerospace Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;2. Jiangsu SinoRoad Engineering Research Institute Co. Ltd., Nanjing 211800, China;3. Jiangsu Highway Engineering Maintenance Co. Ltd, Nanjing210049, China)

Abstract: Epoxy asphalt concrete has been one of the mainstream technology of steel deck pavement in China. But little specification about evaluation system for its distress condition has been researched and maintenance was still unsystematic. The section weight coefficient of different distress is proposed by analyzing the applicability of the “Highway Performance Assessment Standards”. Indexes mainly including SDPCI, PDR and PCR are presented to evaluate its distress condition. The evaluation system and maintenance plan decision tree were recommended, which can assist scientific maintenance of epoxy asphalt steel deck pavement.

Keywords: steel deck pavement; epoxy asphalt concrete; distress condition; evaluation system; maintenance plan

1 Introduction

Epoxy asphalt concrete has been widely used as the steel deck paving material at home and abroad because of its good property such as low temperature performance, high temperature performance and fatigue property[1]. According to research, service life of steel deck epoxy asphalt pavement abroad especially in American can reach more than 20 years without overhauling. For example, the San Mateo-Hayward Bridge applied epoxy asphalt concrete technology for the first time. The bridge has shown good performance for more than 40 years since its operation, and its service life is basically close to the design life of asphalt pavement.

However, it appears serious e arly destruction in steel deck epoxy asphalt pavement at the extreme service condition including high temperature and heavy loads in China[2-5]. There has been just about 10 years in application of epoxy asphalt pavement since first introduced from America on the second bridge on Yangtze River in Nanjing. In addition, the Runyang Yangtze River Bridge, the Su Tong Yangtze River Highway Bridge, etc. all appeared early damage after the use of 3 to 5 years, and entered the centralized maintenance stage. It can be seen that the working condition of epoxy asphalt pavement is not very satisfactory and is far from the situation in foreign countries.

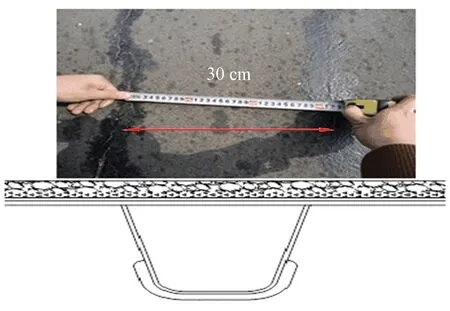

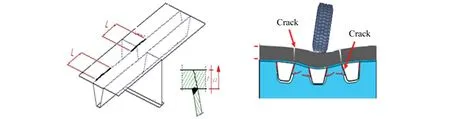

Besides, evaluation system about general asphalt pavements such as “Highway Performance Assessment Standards”are not applicable to steel bridge deck epoxy asphalt pavement[6]because steel deck pavement mechanical characteristics are quite different with general asphalt pavements. For example, longitudinal crack usually appeared on top of U-rib as shown in Fig.1.

In a word, the early distress type of epoxy asphalt pavement on steel deck is different from highway pavement, so it’s necessary to establish special evaluation index. In this paper, section weight coefficient of distress is proposed based on distribution feature, distress type and mechanical characteristics of steel deck epoxy asphalt pavement. In addition, the evaluation system and maintenance plan decision tree is recommended to guide maintenance plan.

Fig.1 Crack on top of U-rib

2 Analysis on Steel Deck Epoxy Asphalt Pavement Distress Characteristics

2.1 Main Distress Type and Development Rule

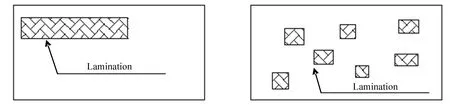

According to local research on different steel deck pavement, the main epoxy asphalt pavement distress type is crack, pothole, patch, lamination, bulge, not including other common distress in general bituminous pavement such as rut, translation and bleeding and so on. Fatigue crack is the initial distress of epoxy asphalt due to both the temperature loads and vehicle loads[7-8]. Fig.2 shows the typical distress of steel deck epoxy asphalt including crack, bulge and lamination.

Fig.2 Cracks, bulge and lamination of steel deck epoxy asphalt pavement

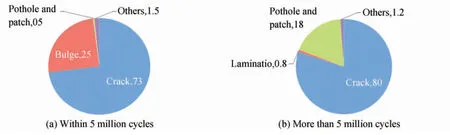

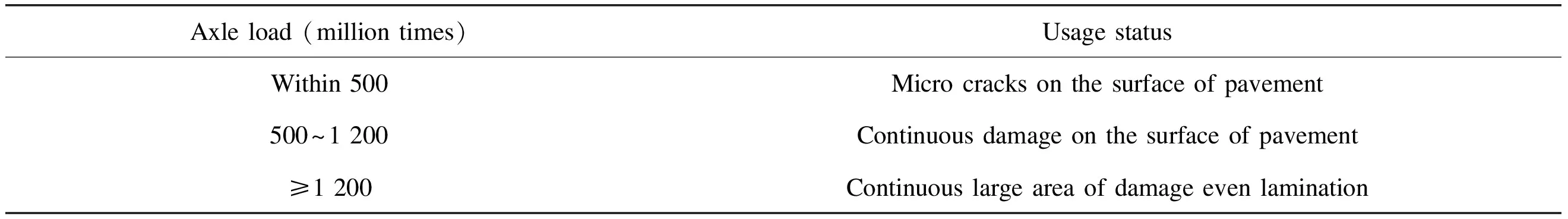

The major difference between the service life and the original design of pavement is that the actual traffic load is much greater than the design load. It was found that the distress development is related to cumulative axle load times.When the cumulative number of axial loads is less than 5 million, the main distress is crack and bulge, of which about 73% are cracks and 25% are bulges; when the cumulative number of axial loads exceeds 5 million, the main distress is crack and pothole. Among them, cracks account for about 80%, and pothole and repairs account for about 18%.

The types and severity of the distress within different cumulative axis loads were shown in Fig.3 and Table 1.

Fig.3 Distress type within different cumulative axis loads

Table 1 Deformation law of epoxy asphalt steel deck pavement

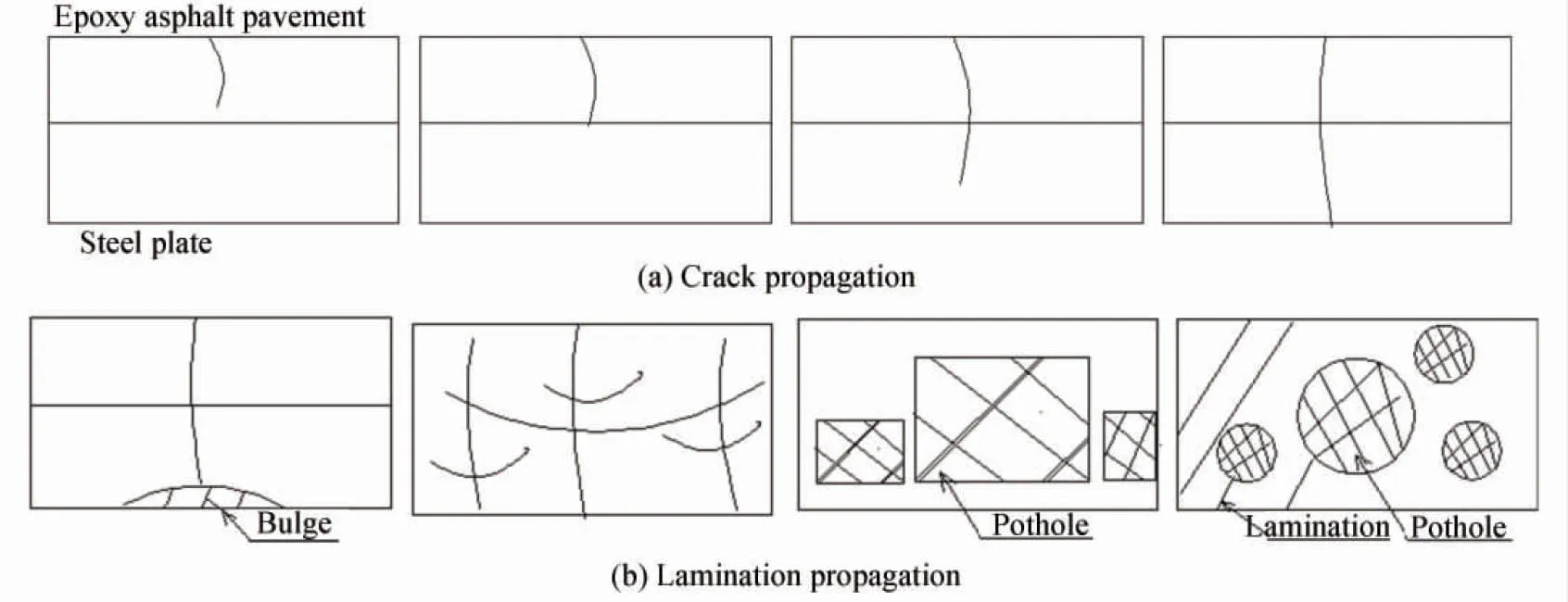

Epoxy asphalt concrete is a thermosetting material and its strength is more than 5 times that of ordinary asphalt mixture. Therefore, steel deck epoxy asphalt pavement is rigid, the main distress development rule[9]was shown in Fig.4.

(1) Fatigue crack occurs on epoxy asphalt pavement under the load;

(2) The crack width gradually widens, and it gradually extends to the steel plate interface under combined environmental loads.

(3) The rain in the crack penetrates into the bottom of the pavement, and constantly corroding the waterproof adhesive layer and mix, which can lead to local disengaging.

(4) The stress condition of the pavement is deteriorated under the wheel load condition, and the part will be crushed to form pothole.

(5) If the pavement pothole is not treated in time, the rainwater would heavily accumulated at the bottom of the pothole and spread extensively to the bottom of the entire lane pavement, which eventually can lead to lamination of the whole lane.

Fig.4 Main distress development rule

2.2 Distress Distribution Characteristics

Accurately understanding and mastering the distress distribution characteristics can provide support for the design of steel deck epoxy asphalt pavement. In order to clarify the distribution characteristics of different pavement distress, the longitudinal distribution characteristics and synergetic analysis of steel box girder structure distress and pavement distress were analyzed.

(1) Longitudinal bridge distress.

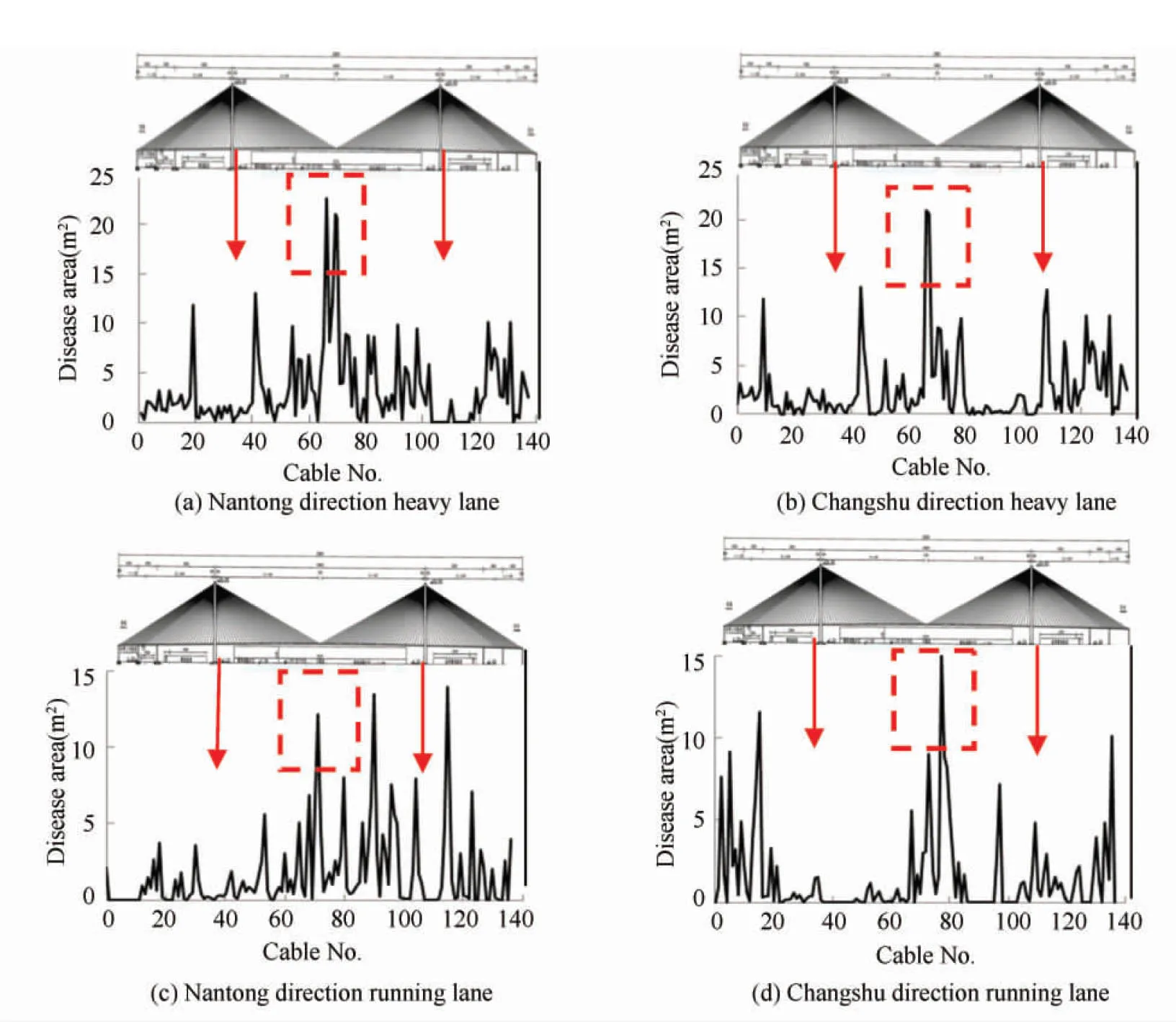

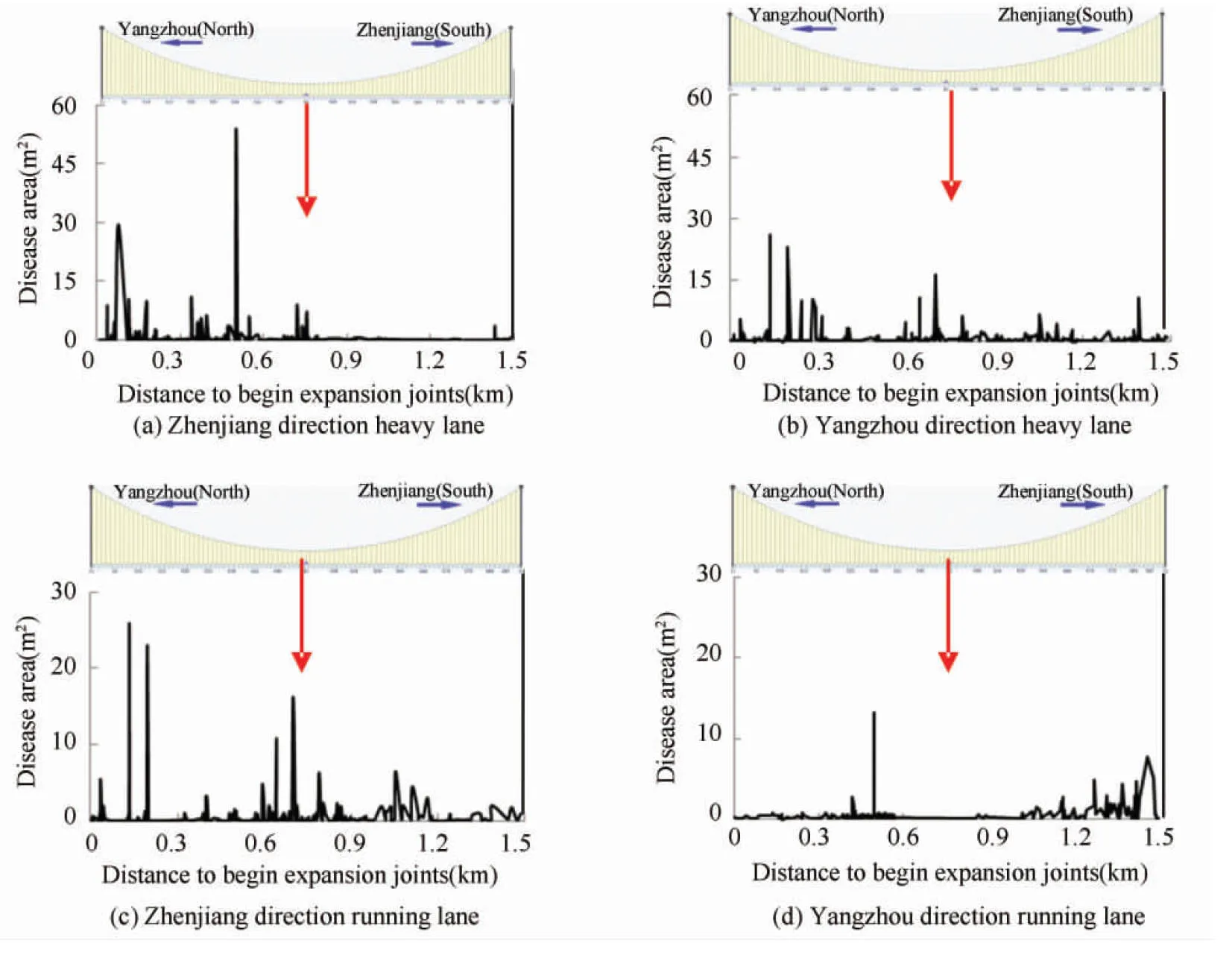

The data of the pavement distress of Su Tong Yangtze River Highway Bridge (cable-stayed bridge, Fig.5) and Runyang Suspension Bridge (Fig.6) was selected to analysis the longitudinal distribution characteristics of different distress by taking the cable number or distance to begin expansion joints and the accumulated distress area as the horizontal and vertical coordinates respectively.

It was found that: (a) there was much distress in heavy lanes than in running lanes; (b) the distress area of the Su Tong Yangtze River Highway Bridge in the middle of longitudinal bridge is about 4 times than the bridge tower. This is because, on the one hand, the mid-span position is a weak part of the road surface with low tensile strength and shear strength; and on the other hand, the stiffness of the bridge tower is relatively large; (c) on the contrary, the central area of the Runyang Suspension Bridge has only a little distress area, which is closely related to the stiffness of the location.

In summary, the distribution of the steel deck epoxy asphalt pavement is not only related to the vehicle load, but also closely related to the bridge structure.

(2) Synergetic analysis of steel box girder structure distress and pavement distress.

The primary distress of steel deck epoxy asphalt pavement was basically longitudinal crack[10]. In order to study the distribution regularity of the key distress of pavement layer in different positions of steel box girder structure, the transverse distribution maps of longitudinal cracks of full bridge were established by combining the corresponding standard layout of steel box girders to realize the synergy analysis of the distress and steel box girder structure, as shown in Fig.7.

The distribution characteristics of longitudinal cracks in the steel deck pavement of a bridge during the past five years were analyzed. The area of longitudinal cracks at different locations were calculated from the left marked center with the length of 3.75 m in each lane, as shown in Fig.8.

Fig.5 Su Tong Yangtze River Highway Bridge’s longitudinal distress

Fig.6 Runyang Suspension Bridge’s longitudinal distress

Fig.7 Orthotropic board-paving system synergies

Fig.8 Synergetic analysis of distress

According to the survey data, it was found that: (a) the area of vertical cracks on the outer edge and the top of U-ribs in the position of the wheel belt and the centerline of the lane account for 80%; (b) when the construction joint is set at the marking line, there are almost no longitudinal cracks in the pavement layer, and when it is set in the lane, it is expressed in the form of secondary cracking of the construction joint; (c) the installation of longitudinal partitions will cause a small number of longitudinal cracks in the vicinity, accounting for 3% of the total distress area.

This is because the maximum tensile stress or tensile strain of the orthotropic steel bridge deck pavement appears on the surface of the pavement, and the maximum lateral tensile stress is located near the top of the trapezoidal stiffener and the top of the mediastinal plate in the pavement. Therefore, longitudinal cracks in pavement are easy to appear on the top of longitudinal stiffeners and the top of the mediastinum.

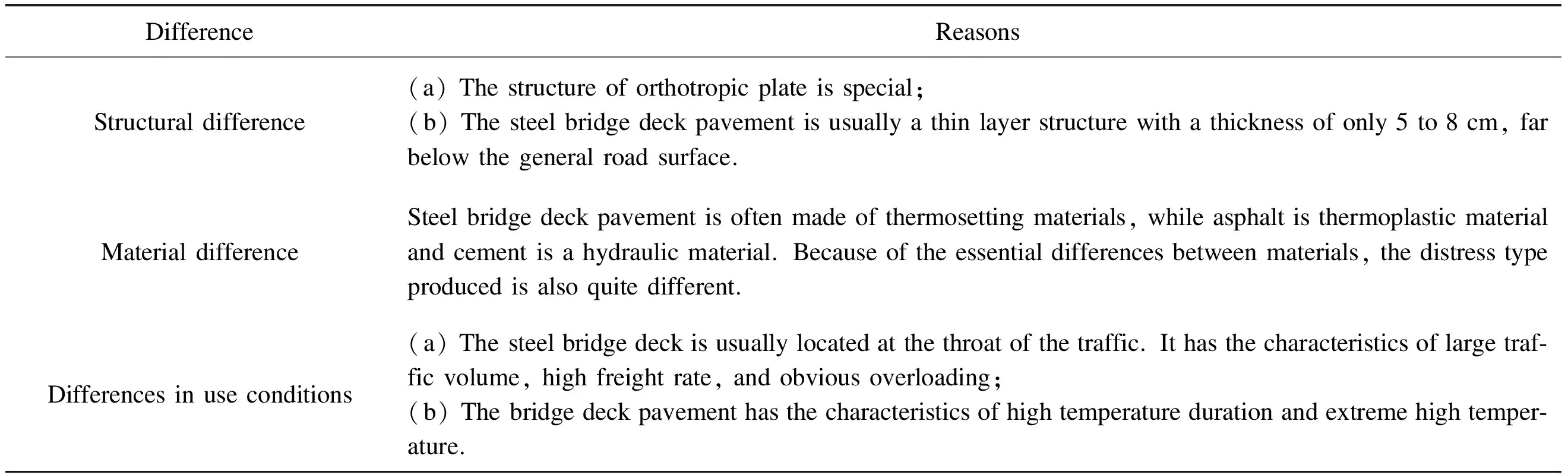

3 Section Weight Coefficient of Steel Deck Epoxy Asphalt Pavement

The existing specification of the “Highway Performance Assessment Standards” cannot evaluate the distress condition of steel deck epoxy asphalt pavement accurately and objectively. The reasons are as shown in Table 2.

Table 2 Reasons for weight coefficient setting

The steel deck epoxy asphalt pavement is usually located in the throat of the traffic with the characteristics of large traffic volume, high freight ratio and overloading phenomenon. Therefore, the weight coefficient of the distress is adjusted according to the Highway Performance Assessment Standards. The contents are as follows:

(1) The asphalt pavement cracks are usually divided into light and heavy grades with the crack width of 3 mm as the boundary.Considering that the thickness of the steel deck pavement is usually thin (only about 5-8 cm), the pavement layer can easily spread to the bottom of the pavement after cracking, so the critical width 1 mm was used to divide the light and heavy degree of the cracks, and the weight coefficients were set to 0.6 and 1 respectively.

(2) Asphalt pavement pothole are usually divided into light and heavy grades. Considering the steel plate will be exposed directly after the occurrence of crack and pothole in the steel deck pavement, the degree of crack and pothole of epoxy asphalt steel bridge were “heavy” by default, and the weight coefficient were set to 1.

(3) The weight coefficient of asphalt pavement repair is usually 0.1. In order to fully reflect the difference between the asphalt and the epoxy material, the weight coefficient of were set to 0.1 and 0.2 individually in the epoxy asphalt steel bridge deck pavement.

(4) Steel bridge deck pavement will occur bulge damage during construction and operation, which can result in the separation of pavement layer and the steel plate, and it is easy to develop cracks, pothole, and other distress under the load. Therefore, the severity of bulge distress was not distinguished, and its weight coefficient was uniformly set to 1.0.

4 Evaluation System of Steel Deck Epoxy Asphalt Pavement Distress Condition

4.1 Assessment Indexes

Main indicators are recommended to evaluate the steel deck epoxy asphalt pavement distress condition including SDPCI(Steel Deck Pavement Condition Index), PDR(Pavement Delamination Ratio), BDD(Bulge Distribution Density), PCR(Pavement Crack Rate), CPR(Crack Penetration Rate), FCS(Fatigue Crack Spacing), PMR(Pavement Maintenance Rate).

1) SDPCI index.

This paper established an evaluation method for the breakage condition of the comprehensive reactive steel deck pavement based on the evaluation method of asphalt pavement damage condition. Firstly, the steel deck epoxy asphalt pavement distress type was classified. Then, the corresponding weight coefficients were assigned of different distress types according to the characteristics of pavement. Finally, the SDPCI index was established. The index of SDPCI can be calculated by formula as follows:

SDPCI=100-a0DRa1

(1)

(2)

where:a0—15.00;a1—0.412;DR—The percentage of distress area to investigation area(%);Ai—Distress area of typeI(m2);A—Investigation area (m2);wi—Weight coefficient of different distress type.

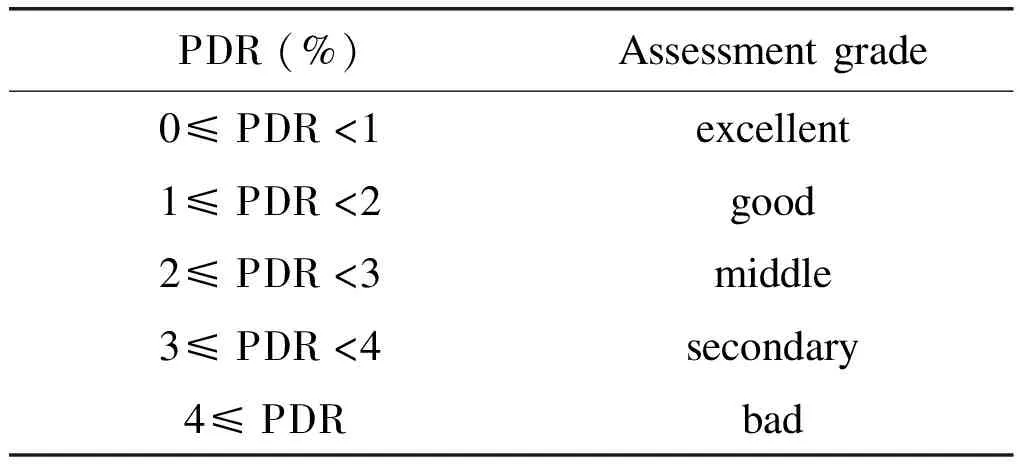

2) Interlayer connection index.

In order to quantify the lamination condition of epoxy asphalt pavement,PDR and BDD were used to conduct macroscopic and microscopic evaluation of the lamination.

(1) PDR Index.

PDR can macroscopically reflect lamination condition and make an overall evaluation of interlayer connection of epoxy asphalt pavement. PDR can be calculated as follows:

PDR=100%×(Aab/A)

(3)

where:Aab—Area of layer lamination (m2);A—Investigated area (m2).

(2) BDD Index.

The BDD index is used to evaluate the density distribution of lamination, as shown in Fig.9. The physical meaning is the average number of voids per 100 m per lane.

(4)

where:NB—The total number of lamination;L—Study lane length (m).

3) Crack Index.

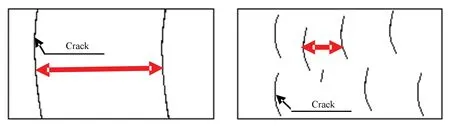

The traditional evaluation of crack mainly considers the width of cracks while neglecting the distribution of cracks and the depth of cracks propagation. In order to further quantify the status of the cracks in steel deck pavement, the PCR, CPR, FCS three indicators were put forward for the comprehensive evaluation of the cracks condition.

(1) PCR Index.

PCR characterizes the overall condition of the cracks, which can be calculated as follows:

PCR=(AC/A)×100%

(5)

where: PCR-Crack Ratio(%);AC-Area of crack (m2), impact width of 0.3 m;A-Area of investigated (m2).

Fig.9 The same lamination area, different distribution density

(2) CPR Index.

The CPR characterizes the percentage of cracks that extend to the steel plate, and the quality of the cracks can be evaluated by the number and proportion of the penetrating cracks. This index can be calculated as follows:

(6)

where: ∑lp—The sum of crack length that extend to the steel plate (m); ∑li— The sum of all crack length (m).

(3) FCS Index.

FCS characterizes the distribution density of vertical crack, as shown in Fig.10. Generally, defects in steel deck epoxy asphalt pavement are mainly longitudinal fatigue cracks and transverse cracks are relatively few. The transverse spacing density was used to calculate the distance between cracks. The formula is as follows:

(7)

where:N—The total number of cracks;L—Length of the surveyed lane.

Fig.10 The same crack area, different distribution density

4) PMR Index.

The PMR value can reflect the overall distress situation of the steel deck epoxy asphalt pavement. The greater the PMR value is, the more serious the pavement distress condition is.

PMR=∑Am/A×100%

(8)

where: ∑Am—The total area of the repair distress;A— The total area of surveyed area.

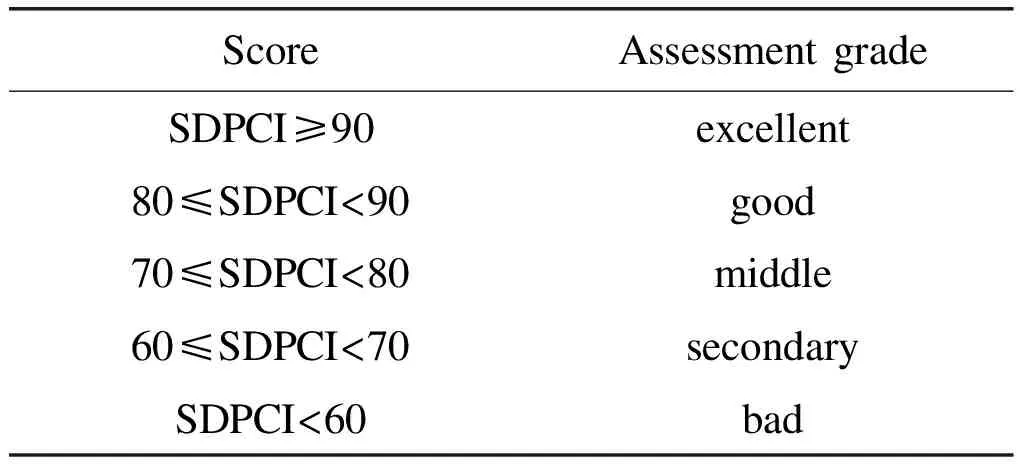

4.2 Assessment Grade

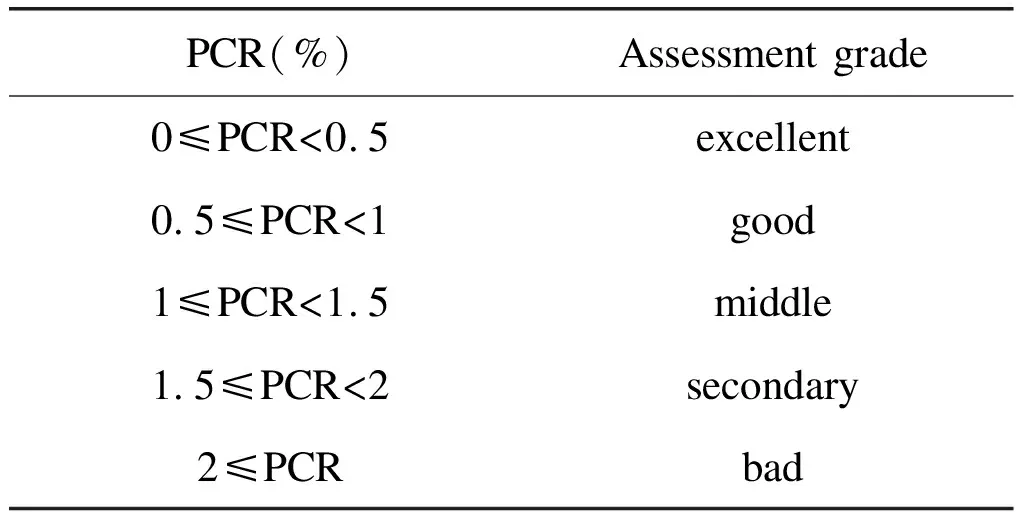

It suggests that the evaluation grades of steel deck epoxy asphalt pavement distress condition are divided into 5 grades, including excellent, good, medium, secondary and poor, as shown in Table 3-Table 5.

Table 3 SDPCI assessment grade

Table 4 PDR assessment grade

Table 5 PCR assessment grade

4.3 Evaluation System

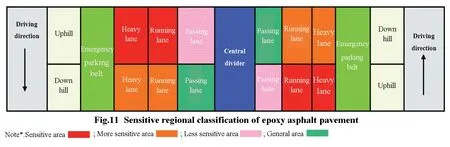

(1) Sensitive regional classification evaluation.

“Highway Performance Assessment Standards” divided the expressways into different lanes or overall to evaluate the pavement performance. In the same way, this paper proposes a grid-based method to evaluate the performance of steel deck epoxy asphalt pavement more precisely, as shown in Fig.11.

According to the distress distribution characteristics, the steel bridge deck pavement is divided according to different lanes, uphill and downhill sections, and the establishment of sensitive regional classification. The evaluation is based on the following aspects: the distress degree of the passing lane is less than heavy lanes and running lanes, and the distress degree of the downhill is less than uphill running lane.

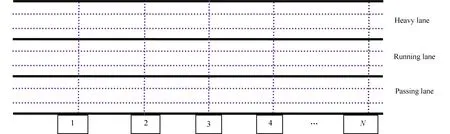

(2) Grid evaluation.

The management method of grid partition evaluation is proposed in order to evaluate the steel deck epoxy asphalt pavement distress condition more elaborately, that is the epoxy asphalt pavement is divided into different sections to highlight the vertical and horizontal distribution of distress characteristics, as shown in Fig.12.

Fig.12 Grid evaluation of epoxy asphalt pavement

Note*:N—Cable or bridge span number

Transverse division: the lanes are partitioned according to the wheel tracks, including the right track zone, the middle track zone, and the left track zone.

Longitudinal division: full bridge length is divided by cable or bridge span, two adjacent cables are seen as a unit area or a span.

5 Classification of Maintenance and Management

5.1 Forecast SDPCI Index

Steel deck epoxy asphalt pavement remaining performance is one of the important reference factors in the decision making the maintenance program. How to make full use of the remaining performance of pavement and timely carry out targeted conservation is undoubtedly a key technical problem to be solved in the current steel deck pavement maintenance and management.

The influence of epoxy asphalt pavement age, bridge structure and traffic load on the residual performance of deck pavement were comprehensively analyzed according to experience. A comprehensive coefficient ofCfor residual performance was established, which provides a reference for further research on residual performance of steel deck pavement. The following equation shows how to calculate the SDPCI index considering the residual performance reduction. The forecast SDPCI index calculation formula is given and the relevant values are calculated.

SDPCIC=SDPCI×C

(9)

C=Cst×CSCl

(10)

CS=Ct×Cd

(11)

Cl=Clb×Csp

(12)

where: SDPCIc—Forecast SDPCI index;

Cst—Environmental aging influence coefficient, when the road age is within 5 years, theCstvalue is 1, after every 5 years, theCstvalue was reduced by 0.02;

Ct—Bridge structure influence coefficient, theCtof continuous girder bridges takes 1; the cable-stayed bridgeCttakes 0.99; the suspension bridgeCttakes 0.95;

Cd—plate thickness influence coefficient, theCdof thickness 18 mm takes 1; theCdof thickness 16 mm takes 0.99; theCdof thickness 14 mm takes 0.95; theCdof thickness 12 mm takes 0.85;

Cl—Lane truck load influence coefficient;

Clb—Lane influence cardinality, theClbof Heavy Lane takes 0.9; theClbof Running Lane takes 0.95; theClbof Passing Lane takes 1;

Csp—Slope influence coefficient, theCspof Uphill takes 0.95; theCspof Downphill takes 0.98.

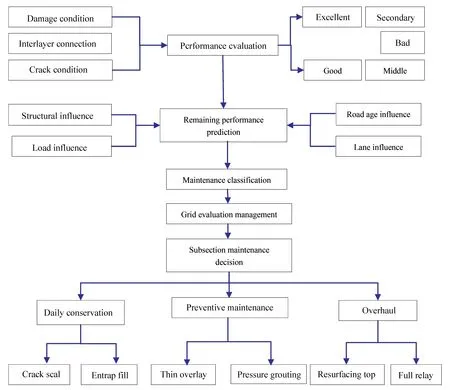

5.2 Decision Tree of Maintenance Management

Maintenance of steel deck epoxy asphalt pavement is divided into three stage plan, including daily conservation, preventive maintenance, and overhaul. Maintenance decision tree was shown in the Fig.13.

Fig.13 Maintenance decision tree of steel deck epoxy asphalt pavement

(1)Through the patrolling inspection and subsequent indoor data analysis, the SDPCI, PDR and PCR equivalent of steel deck epoxy asphalt pavement were calculated respectively to comprehensively evaluate the technical conditions of the epoxy asphalt pavement.

(2)The prediction of epoxy asphalt pavement performance was carried out considering the influence of bridge structure, the thickness of the orthotropic plate, lane distribution and so on.

(3)According to the information of performance evaluation and residual performance prediction, the maintenance grade of epoxy asphalt pavement is determined, and the local distribution of bridge damage is analyzed, gridded partition is carried out.

(4)According to the steel deck epoxy asphalt pavement performance evaluation method of grid partition, maintenance level and the remaining performance of epoxy asphalt pavement, so as to carry out section maintenance management of epoxy asphalt pavement, including daily conservation, preventive maintenance and overhaul.

6 Conclusions

(1)The main distress type of steel deck epoxy asphalt pavement is crack, layer lamination, patch, pothole and others. And the development is related to cumulative axle load times, when the cumulative number of axial loads is less than 5 million, the main distress is crack and bulge; when the cumulative number of axial loads exceeds 5 million, the main distress is crack and pothole.

(2)The distress distribution characteristics of steel deck epoxy asphalt pavement are related to the bridge type structure. The distress area of the Su Tong Yangtze River Highway Bridge in the middle of longitudinal bridge is about 4 times than the bridge tower. On the contrary, the central area of the Runyang Suspension Bridge has only a little distress area, which is closely related to the stiffness of the location.

(3)The area of vertical cracks on the outer edge and the top of U-ribs in the position of the wheel belt and the centerline of the lane account for 80%, and the installation of longitudinal partitions will cause a small number of longitudinal cracks in the vicinity, accounting for 3% of the total distress area.

(4)Section weight coefficient of steel deck epoxy asphalt pavement is proposed to help evaluate the service condition of pavement, and the assessment matrix is introduced based on indexes including SDPCI, PDR and PCR.

(5)The maintenance decision tree is built by steel deck epoxy asphalt pavement distress condition grade, including daily conservation, preventive maintenance,and overhaul.

Journal of Harbin Institute of Technology(New Series)2019年5期

Journal of Harbin Institute of Technology(New Series)2019年5期

- Journal of Harbin Institute of Technology(New Series)的其它文章

- Standardization of Robot Instruction Elements Based onConditional Random Fields and Word Embedding

- Study on Thermal Deformation Measurement of Optical Remote Sensing Satellite Platform Based on Machine Vision

- Novel Logarithmic Non-Singular Terminal Sliding Mode and Its Application in Attitude Control of QTR

- Initial Phase Properties and Anti-interference Capability of Memristor Models

- Review: Recent Advancement of Experimental and Numerical Investigations for Breaking Waves

- Relationship on the Head Deviation Rate and Laying Length of Porous Tubes