The Application of Modified Oil Ethoxylates in Laundry Beads Formulation

Shanghai Fine Chemical Co.,Ltd.,China

Abstract The flow ability,foam,and detergency performance of SOE-N-60 are introduced,the advantages of its application in the formulation of laundry beads are analyzed.Then,the formulation of laundry beads based on SOE-N-60 was developed.The results showed that SOE-N-60 has low foaming performance and excellent flow ability at low temperature,and it can maintain good liquidity of the mixed system,the laundry beads formulation has low foaming performance and its detergency meets the industry standards.

Key words laundry beads; SOE-N-60; low temperature fluidity; formulation stability; low foaming property

Nowadays,green,concentrated,and convenient to use are the main development directions of domestic liquid detergent,[1]laundry beads are made by coating super concentrated liquid detergent with water-soluble polymer membrane.They are crystal and fashionable in appearance,accurate in measurement,convenient in use and no harm to hands.The outer membrane dissolved when the beads put into water,and the wrapped detergent released into the water to clean clothes.[2]Due to their super concentrated formulations,only one or two laundry beads are needed for a whole barrel of clothes,and its efficiency is often higher than that of traditional power and liquid detergent.Therefore,laundry beads have become one of the main directions for the structural adjustment and upgrading of washing products.

For the water-soluble outer layer polymer membrane,the detergent inside is usually low water formulation,maybe less than 5%.At such low water content,some commonly-used anionic surfactants,such as sodium alkyl benzene sulfonate,fatty acid methyl ester and α-alkenyl sulfonate,cannot be completely dissolved,resulting in stratification after long standing.[3]The active content of laundry beads is usually higher than 45%,under such high content,traditional non-ionic surfactant fatty alcohol polyoxyethylene ether series are easy to gel.[4]Therefore,the selection of suitable surfactants is very important for the stability,dispersion solubility and washing performance of beads.

Modified oil ethoxylates SOE-N-60 is a green non-ionic surfactant made from natural oils through ethoxylation.Its mild,low irritation,stable and flowable at low temperature,miscibility with water and no gel,low foam,and easy rinse,[5]can be used as an ideal surfactant for the formulation of laundry beads.This paper introduced the basic properties of SOE-N-60,use SOE-N-60 as main surfactant and traditional anionic and nonionic surfactants as compound surfactants,based on the formulation optimization,the detergency of the formulation was also investigated.

1 Experimental section

1.1 Materials

Modified oil ethoxylates SOE-N-60,fatty alcohol ethoxylates AEO9,Fatty acid methyl ester ethoxylates FMEE-68-15,isomeric alcohol ether IAEO (Industrial grade,Sinolight Surfactants Technology Co.,Ltd.);Fatty alcohol ether sodium sulfate AES and Linear alkylbenzene sulfonate LAS (Industrial grade,Sinolight Shaoxing Chemicals Co.,Ltd.); Fatty acid methyl ester sulfonate MES (Industrial grade,Zanyu Technology Group Co.,Ltd.); Alkyl polyglycosides APG1214 and Sodium fatty alcohol ether carboxylate AEC (Industrial grade,Shanghai Fine Chemical Co.,Ltd.); Glycol and Glycerol (Analytically pure,Sinopharm Chemical Reagent Co.,Ltd); Standard stain cloths JB-01,JB-02,JB-03 (China Research Institute of Daily Chemical Industry); Deionized water.

1.2 Methods

1.2.1 Foaming property

The foaming properties of the surfactant and the compounds are tested according to the improved Ross-Miles method (GB/T 7462-1994).The surfactants were dissolved with 3 mmol / L CaCl2hard water to prepare an aqueous solution with effective content of 0.25%(mass fraction),and the test was carried out at 50 °C,then the foam volume (mL) at 30 s,3 min,5 min was recorded after the test.The larger the foam volume,the higher the foam performance.

1.2.2 Detergency index

The detergency index of the surfactants and the compounds are determined according to method GB/T 13174-2008,the surfactants are dissolved with 250 mg/L hand water and the aqueous solution with a mass fraction of 0.2% was obtained.The vertical decontamination machine was used to carry out decontamination experiments on national standard dirty cloth jb-01,jb-02 and jb-03 at (30 ± 1) °C.The whiteness of all cloth before and after washing was tested and the difference was calculated.The detergency index is calculated by dividing the whiteness difference of the test sample by the result of the standard detergent.If the index≥1,which means the detergency meets the requirements of the national standard.

1.2.3 Pour point

Take appropriate amount of surfactant sample into a 20 mL tube,observe the flow state of the sample according to the method of GB/T 3535-2006,and record the pour point temperature of the sample.

1.2.4 Cloud point

Deionized water was used to prepare 1% surfactant aqueous solution,stirring until completely dissolved.Take 15 mL of the surfactant solution into 20 mL transparent test tube with thermometer.Gradually raise the temperature under water bath condition,and stir the solution slowly at the same time.The temperature when the solution changes from clear and transparent is the cloud point temperature.

1.2.5 Gel range

The surfactant was dissolved with deionized water to prepare aqueous solutions with mass fraction of 10%,20%,30%,40%,50%,60%,70%,80%,90%.The above aqueous solutions were enclosed in a plug test tube and placed in a 25 °C incubator.The gel state was observed after 24 h and the gel range was determined.

2 Results and discussions

2.1 Basic performance of SOE-N-60

SOE-N-60 is a new green surfactant with mild property.SOE-N-60 has low pour point and have good fluidity even at -12.5 °C.No gel occurs in SOE-N-60 aqueous solution at any concentration.The cloud point of SOE-N-60 is 58 °C,so there are no turbidity or stratification of aqueous solution in normal storage temperature.The low pour point and the no gel characteristics of SOE-N-60 make it an ideal raw material for laundry bead formulations.

2.2 Foaming property and detergency of SOE-N-60

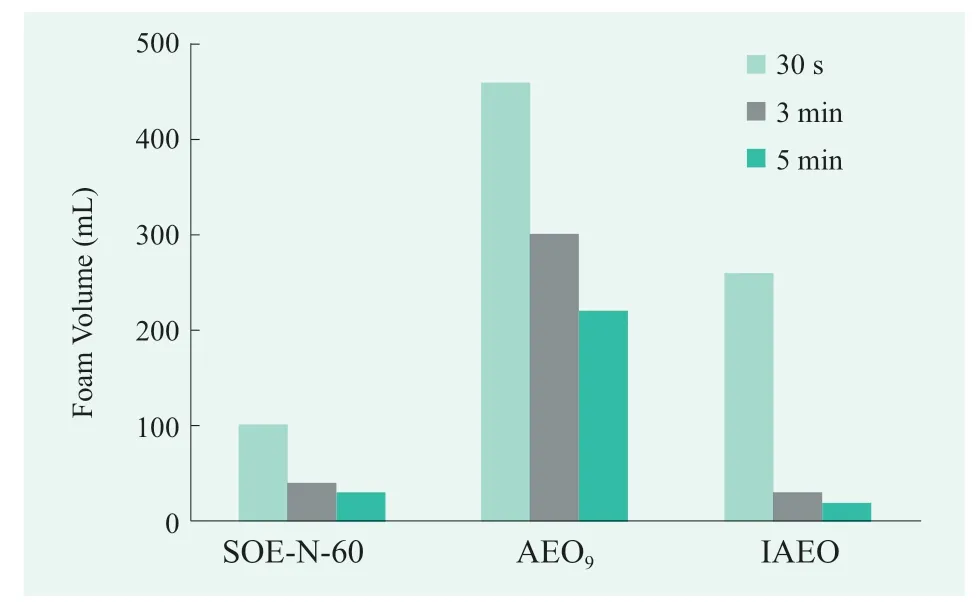

The foaming property of SOE-N-60,AEO9and isomeric alcohol ether IAEO were investigated and the experimental results are shown in Figure 1.As we can see that the foam volume of SOE-N-60 is 100 mL at 30 s,much lower than that of AEO9,also lower than that of IAEO,indicating that the foaming capability of SEO-N-60 is very low.At 3 min and 5 min,the foam volume of SOE-N-60 is also less than AEO9,and equivalent to that of IAEO,which means the defoaming speed of SEO-N-60 is fast.The low foaming performance and fast defoaming speed of SOE-N-60 can reduce the rinsing times and improve the rinsing efficiency.From the foam performance,SOE-N-60 is an ideal raw material for laundry beads formulations.

Figure 1.Foam properties of SOE-N-60,AEO9 and IAEO

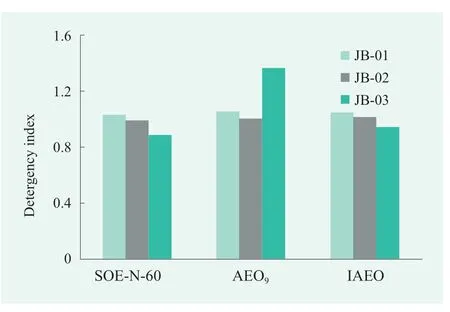

The detergency index of SOE-N-60,AEO9and IAEO are shown in Figure 2.It can be seen that the detergency index of SOE-N-60 for JB-01 and JB-02 are equivalent to that of AEO9and IAEO,

Figure 2.Detegency index of SOE-N-60,AEO9 and IAEO

while the detergency index of SOE-N-60 for JB-03 is equivalent to that of IAEO and slightly weaker than AEO9.Commonly,we can improve the detergency of surfactant by compounding with other surfactants.

2.3 Compatible stability of SOE-N-60 under low water content

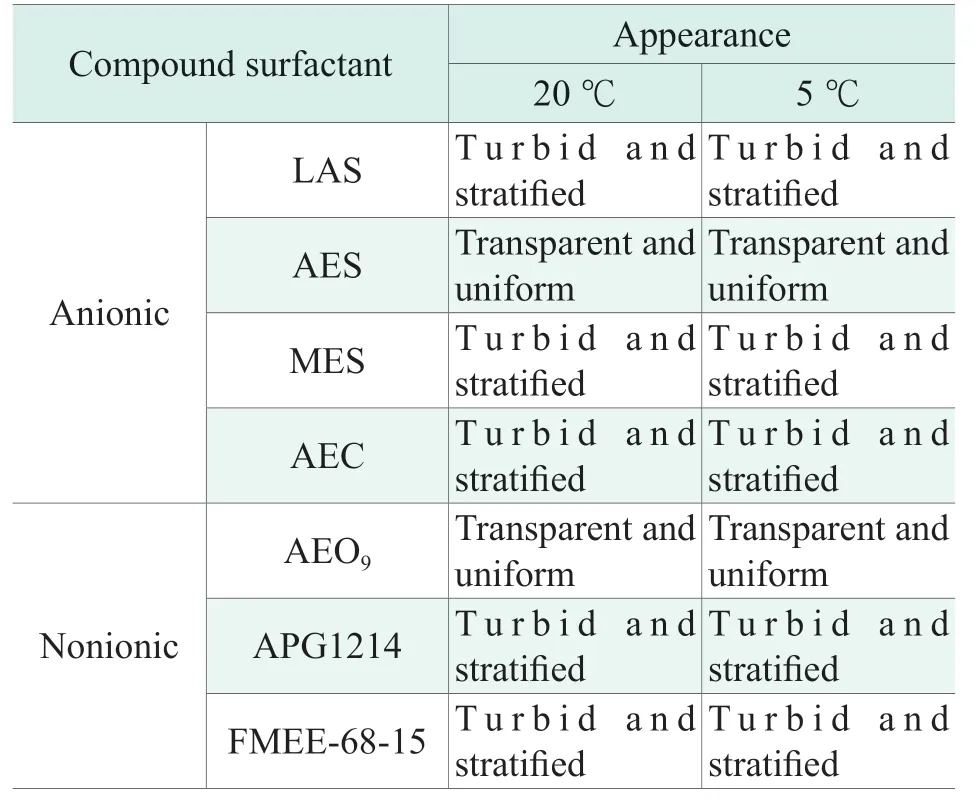

SOE-N-60 was compounded with LAS,AES,MES,AEC,AEO9,APG1214 and FMEE-68-15,respectively,with the mass ratio of 20 : 7 : 3(SOE-N-60 : compound surfactant : water),and total water content was controlled at 10%.The compound samples were placed in incubators at 20 °C and 5 °C for 24 h.The appearance of the composite samples was observed.The results are shown in Table 1.

Table 1.Formulation stability of SOE-N-60 and common anionic and nonionic surfactants

As we can see from the table that when anionic surfactants LAS,MES,AEC mixed with SOE-N-60,the appearance of the mixtures is turbid and stratified no matter at 20 °C or 5 °C,it is possible that these surfactants are usually solid state and cannot be completely dissolved at such low water content,resulting in turbidity and stratification after compounding.AES can be quickly dispersed and dissolved when mixed with SOE-N-60,and the solution is transparent and homogeneous.Among the alternative nonionic surfactants,only AEO9show transparent and uniform state when compounded with SOE-N-60,which may be due to the similar structure of AEO9and SOE-N-60,so they are miscible.

2.4 Detergency of the compound surfactants

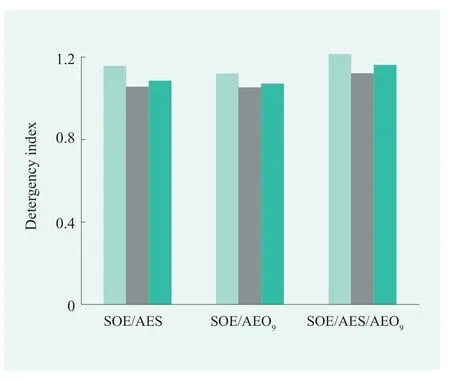

SOE-N-60 has excellent fluidity and stability even at low temperature,but when it is used alone,its detergency,especially the detergency for JB-03 is slightly weak (see Figure 3).Therefore,it is hoped that the detergency of SOE-N-60 can be improved by compounding with other surfactants.According to the results of compatibility stability,the detergency of the mixed system: SEO-N-60,AES and AEO9was studied.The mass ratios of the composite systems are: SOE-N-60 and AES (2:1),SOE-N-60 and AEO9(2:1),SOE-N-60 and AES,AEO9(the mixture ratio is 2:1).The detergency index of these three composite systems is shown below.It can be seen from Figure.3 that compared with SOE-N-60 (see Figure 2),the detergency index of the composite systems is increased,especially for the ternary system.On the comprehensive consideration of compatibility stability and detergency,SOE-N-60 was selected as the main surfactant,AES and AEO9as the composite surfactant as the basic formula raw materials for laundry beads.

Figure 3.Detergency index of the mixed systems

2.5 Basic formulation of laundry beads

Commonly,the mass faction active content of laundry beads is generally higher than 45%,usually 60% or higher,and a certain amount of organic solvents such as glycol and glycerol will be added to further improve the fluidity and low temperature stability of laundry beads.SOE-N-60 was compound with AES with mass ratio of 20 : 7,and then AEO9was added to the mixed system,through a large number of compound experiments,it was found that when the mixing ratio of SOE-N-60,AES,AEO9was 20 : 7 :8,they had good low temperature stability,and could keep transparent and uniform appearance.Finally,the optimized basic formulation was obtained: SOE-N-60 was 40% (mass fraction),AES was 14%,AEO9was 16%,glycol was 15%,and glycerol was 15%.The results show that the laundry bead formulation is transparent and uniform in appearance even at 0 °C,has good low temperature stability,and can disperse and dissolve rapidly in water.

3 Conclusion

The modified oil ethoxylate SOE-N-60 has excellent fluidity and low temperature stability,as well as low foaming property,it can be dissolved in water at any concentration with no gel.Under low water content SOE-N-60 good compatibility with AES and AEO9,and its detergency is significantly improved after compounding.

China Detergent & Cosmetics2021年1期

China Detergent & Cosmetics2021年1期

- China Detergent & Cosmetics的其它文章

- Specification on cosmetics registration record ready to be operated

- Risk Analysis and Quality Control of Cosmetic Raw Materials

- Efficacy Evaluation of a Compound Plant Extract Used in Makeup Base

- Study on the Anti-inflammatory and Repairing Effects of Cannabis Sativa Leaf Extract by Epikutis Model Substitution

- Laboratory Study on the Whitening Ability of A New Type of Toothpaste Against the Tobacco Stains on Teeth

- Research and Application of Nanofiber Technology in Mask Products