Effect of heat treatment on the microstructure and mechanical properties of AZ80M magnesium alloy fabricated by wire arc additive manufacturing

Yngyng Guo,Gofeng Qun,*,Mert Celikin,Lingo Ren,Yuhng Zhn,Lingling Fn,Houhong Pn,*

a Key Laboratory of Advanced Technologies of Materials,Ministry of Education,School of Materials Science and Engineering,Southwest Jiaotong University,Chengdu,Sichuan 610031,PR China

b School of Mechanical and Materials Engineering,University College Dublin,Belfield,Dublin 4,Ireland

cCenter for Advancing Materials Performance from the Nanoscale,State Key Laboratory for Mechanical Behavior of Materials,Xi’an Jiaotong University,Xi’an 710049,PR China

Abstract To maximize the benefits of wire arc additive manufacturing(WAAM)processes,the effect of post-deposition heat treatment on the microstructure and mechanical properties of WAAM AZ80M magnesium(Mg)alloy was investigated.Three different heat treatment procedures(T4,T5 and T6)were performed.According to the results,after T4 heat treatment,the microsegregation of alloying elements was improved with the eutectic structure dissolved.Samples after T5 heat treatment inherited the net-like distribution of secondary phases similar to the as-deposited sample,where the eutectic structure covering the interdendritic regions and the β-phase precipitated around the eutectic structure.After T6 heat treatment,the tiny β-phases re-precipitated from the matrix and distributed in inner and outer of the grains.The hardness distribution of the samples went through T4 and T6 heat treatment was more uniform in comparison to that of T5 heat treated samples.The tensile test showed that the T6 heat treatment improved the strength and ductility,and the anisotropy between horizontal and vertical can be eliminated.Moreover,T4 treated samples exhibited highest ductility.

Keywords:Wire arc additive manufacturing;AZ80M magnesium alloy;Heat treatment;Microstructure;Mechanical properties.

1.Introduction

Being the lightest structural metal(1.74 g/cm3),magnesium(Mg)alloys have the characteristics of high specific strength,excellent damping performance and electromagnetic shielding performance,and have great potential for weight reduction and energy saving.However,aluminum(Al)alloys with higher density(2.7 g/cm3)are still the preferred choice for lightweight design in the fields of aircraft,automobile and high-speed trains even though Mg alloys have a wide range of application prospects[1].One of the main factors limiting the use of Mg alloys is the poor formability due to hexagonal close-packed(HCP)crystal structure and strong heat dissipation tendency,making the traditional manufacturing processes like forging and rolling at room temperature unfeasible.Additionally,Mg casting process is accompanied by defects such as coarse grains,shrinkage cavity and slag inclusion,which makes the performance of the formed parts difficult to meet the requirements[2,3].Therefore,there is an urgent need for new methods to manufacture integral Mg alloy parts.

Wire arc additive manufacturing(WAAM)is an innovative technology developed in the past few years,for which manufacturing industry has shown great interest.WAAM used electric arc as the heat source and metallic wire as the feed material,the energy and the material usage efficiencies of WAAM were much higher(up to 10 kg/h deposition rates can be achieved)than the other additive manufacturing processes such as Selective Laser Melting(SLM)[4].More valuably,the WAAM process can be operated in open air as localized inert gas shielding is only required around the slowly moving fusion zone,which means that the WAAM can be used to fabricate large size structures up to several meters in dimension without the limitation of equipment workbench[5].WAAM have already been applied to various metallic materials,such as titanium(Ti)[6–8],steel[9,10],aluminum(Al)[11–13]and nickel(Ni)[14,15]alloys and their intermetallic composites(IMC)[5,16,17].A few studies on the WAAM of Mg alloys have been reported in recent years.WAAM was preliminarily applied to fabricate AZ31 Mg alloy by Guo et al.[18]and it was determined that the use of pulsed frequency resulted in the change of weld pool oscillations and cooling rate,further led to the change of the grain size,orientation,as well as the tensile properties.WAAM based on cold metal transfer(CMT)process of AZ31 Mg alloy proposed has shown non-homogenous microstructure,hence tensile properties present anisotropic characteristics because of the epitaxial columnar dendritic growth along the building direction[19].

Since the high heat input and rapid solidification nature of the WAAM deposition process,the materials fabricated exhibit a layered structure and the formation of non-equilibrium phases significantly restricts the service performance of the components.The layer-by-layer deposition resulted in serious thermal accumulation,and the arc energy not only caused partial melting and heat treatment of the previously deposited layers but also extended a non-isothermal heat treatment effect up to three to four layers below the deposited bead[20].This can significantly influence the microstructure and the mechanical properties of the WAAM materials,leading to anisotropy.Tensile anisotropy in the horizontal and vertical directions of the WAAM components were reported when fabricated 5A06 Al[11],316L SS[9]and AZ80M Mg alloys[21].

Recent studies focused on the ways to avoid or decrease anisotropy in WAAM materials as it is crucial for widening the application range.To optimize the mechanical properties,Ma et al.[16]carried out post-deposition heat treatments which resulted in more uniform microstructure and minimized tensile anisotropy in WAAMγ-TiAl IMC.Gu et al.[12,22]applied a hybrid technique of inter-layer rolling and heat treatment to WAAM Al alloys,which resulted in improved microstructural homogeneity and weakened anisotropy of mechanical properties.Fu at al.[10]developed an hybrid deposition and micro-rolling(HDMR)process to eliminate the anisotropy of the WAAM bainitic steel upon the multi-layer and multi-pass deposition.However,up to now,there is no report on the post-deposition heat treatment of WAAM Mg alloys.AZ80 is widely used because of its good strength,corrosion resistance and plastic processing properties.Moreover,microalloying has been reported to be beneficial for improved mechanical and thermal performance of Mg-Al-based systems.Y can not only refine the grains in the Mg alloys but also improve the thermal stability of the Mg alloys through forming a new stable secondary phase Al2Y in Mg-Al alloys[23];the addition of trace Ca can improve the ignition pointand high temperature oxidation resistance of Mg alloy and reduce the burning loss of elements in the melting process[24].In this study,customized AZ80M(AZ80 with Y+Ca microalloying)was chosen as the raw material.The objective was to understand the effect of various heat treatments(T4,T5 and T6)on the microstructural evolution and mechanical properties of WAAM AZ80M Mg alloy,which could lay the foundation for the application of WAAM Mg alloys.

2.Experimental procedure

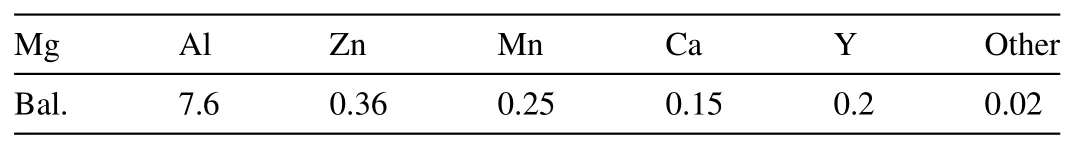

Extruded substrate dimensions were 8 mm thickness,80 mm width and 300 mm length.The same chemical composition AZ80M wire with a diameter of 1.6 mm was used as filler metal.The chemical composition details of AZ80M Mg alloy are listed in Table 1.

Table 1The chemical composition of AZ80M Mg alloy(wt.%).

The schematic of the manufacturing process of arc additive process is shown in Fig 1a.The gas tungsten arc welding(GTAW)equipment used was a WSE-315D power supply with pulse current mode.The welding torch was fixed on the welding trolley to realize one-way reciprocating movement,and the deposition path was unidirectional.The output type of the welding power was AC pulse,and the main process parameters were given in Table 2.Each sample was deposited with 50 layers,and a typical deposited thin-wall component is shown in Fig.1b.

Referring to the conventional heat treatment methods[25],the post-deposition heat treatment of the AZ80M Mg alloy included solution treatment(T4),direct artificial aging treatment(T5)and solution+artificial aging treatment(T6).The process details are given in Table 3.The heat treatment experiment was carried out in air by using medium temperature resistance furnace.

Table 2The process parameters of WAAM AZ80M Mg.

Table 3The parameters of heat treatment process.

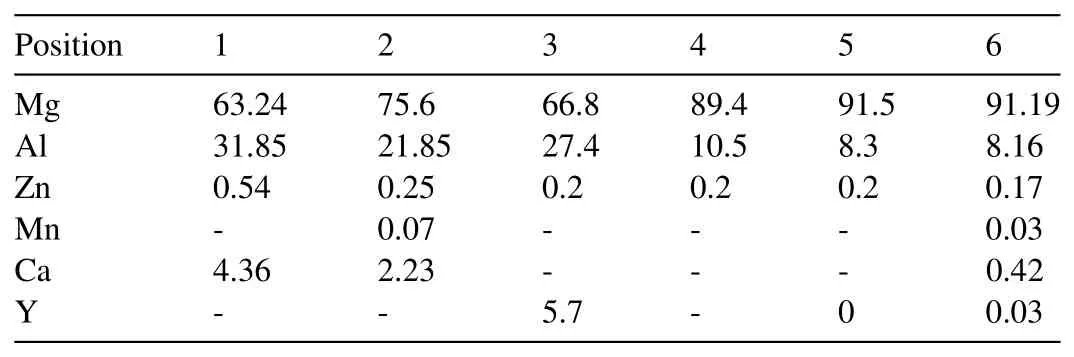

Table 4Chemical composition of different position marked in Fig.3 obtained by EDS.

Microstructural characterization and mechanical testing of the deposited wall were conducted after removing the edge zone.Samples for the observation of the microstructure were cut along the building direction.After grinding and polishing,the samples were etched using picric acid(4.2 g picric acid,10 ml acetic acid,10 ml distilled water,100 ml alcohol).The samples were analyzed by A1 Zeiss optical microscope and Quanta FEG 250 scanning electron microscope(SEM)equipped with energy dispersive spectroscopy(EDS).The accelerating voltage was set to be 15 kV.The phase composition was analyzed by PANalytical X′Pert Pro with Cu Kα1 radiation(λ=0.154 nm),and the selected parameters were 40 kV,40 mA with the angle range of 2θ=20-80°(scan step size

0.013°,time per step 8.67 s and scan type was continuous).

Fig.1.Schematic of the WAAM system(a)and appearance of single pass 50 layers specimen(b).

Fig.2.Sampling of WAAM AZ80M wall(a)the tensile sample orientation and sampling position;(b)sampling characteristics for tensile test;(c)sample size for tensile test.

The deposited component was subjected to tensile testing with samples oriented in two different directions as shown in Fig 2a,(i)parallel(horizontal samples)and(ii)perpendicular(vertical samples)to the deposition direction.As the thickness of the deposited wall was between 8–11 mm,three sheet samples were cut form each tensile sampling location(Fig.2b).Sampling feature and size of the specimen are shown in Fig.2c.The tensile testing was carried out on MTS-CMT5105 universal testing machine with strain rate of 1 mm/min.The Vickers hardness testing was carried out using the HVT-1000A microhardness tester with a load of 1.96 N and a holding duration of 15 s.Each sample was tested for 36 points in a 6×6 array on the section of the sample with an interval of 0.2 mm.The hardness distribution map was drawn after removing the noise and invalid points(such as the points on the porosity).

3.Results and discussion

3.1.Microstructural characterization

The microstructure of WAAM AZ80M under different heat treatment are shown in Fig.3.It can be seen from Fig.3a that as deposited AZ80M Mg alloy possesses a typical ascast microstructure with both interdendritic and intradendritic second phases.SEM analysis(Fig.3b)shows coring effect along the dendrites as well as discontinuous particle-like interdendritic phases.Consistently,according to EDS analysis results(Table 4),the interdendritic second phases were determined to be the divorced eutectic structures ofα-Mg andβ-Mg17Al12along with Ca/Y concentrated particles with high thermal stability due to their limited solubility formed by nonequilibrium solidification during the arc deposition process.Fig.3c and d show the microstructure after T4 heat treatment.It can be seen from Fig.3c that most of the secondary interdendritic phases with low thermal stability(β-Mg17Al12)were dissolved back to the Mg matrix lead to the disappearance of the net-like structure.Mainly Ca and Y concentrated particles were remained after T4 treatment due to their higher thermal stability.Ca,as a microalloying element,could replace Mg atom inβ-Mg17Al12to enhance covalent bond strength and noncovalent bond strength of Mg-Mg atom,so as to improve the thermal stability ofβphase[24].SEM analysis upon T4 heat treatment(see Fig.3d)showed that the size and quantity of the gray white granular eutectic phase were significantly smaller than that of as-deposited condition.On the other hand,the microstructural analysis after T5 heat treatment(shown in Fig.3e and f)indicated that additional second phases formed adjacent to the interdendritic and intradendritic second phases.SEM observation(Fig.3f)showed,in addition to the existence of the original divorced eutectic structure,discontinuous precipitation(DPs)with different morphology was present,which is a typical morphology for DPs ofβ-Mg17Al12(in Table 3)[25].Microstructural evolution upon T6 heat treatment are shown in Fig.3g and h.It was found that due to the solution treatment,secondary phases are mainly dissolved which allowed the observation of fine equiaxed grain structure.Moreover,the ageing treatment caused the formation of more evenly distributed smaller continuous precipitates(CPs)in comparison to T5 condition.Even though bulk secondary phases were mainly disappeared leaving only Ca/Y rich particles,discontinuous interdendriticβ-Mg17Al12precipitation was still present along with thermally induced fine intradendritic precipitates.

Fig.4 shows the element distribution of WAAM AZ80M Mg alloy under different heat treatment conditions obtained by EDS mapping.The element with the most obvious change should be Al and Zn,which is also the main alloying element of AZ80M.As shown in Fig.4a,the distribution of Al and Zn elements in the AD sample was uneven,with higher concentration in the secondary dendrite and grain boundary,but less in the matrix.After T4 and T6(Fig.4a and d)heat treatment,the distribution of Al and Zn elements became more evenly distributed,while no obvious change in T5 sample(Fig.4c).Moreover,the distribution of Ca and Y had no obvious change because of the formation of(Mg,Al)2Ca/Al2Y phases with higher melting point and higher thermal stability[26].

Metallic parts prepared by WAAM have layered structure,which have also been reported in Al alloys[27]and steel[28].The main reason for the formation of such inhomogeneity is that the microstructure after solidification is determined by the temperature gradient inside and outside the melt pool and the cooling rate,while the different positions of the deposition layer have different heating and cooling rates.Therefore,the effect of different heat treatment on the layered structure of WAAM AZ80M Mg alloy was also studied.Fig.5 shows the layered structures under different heat treatment states.As shown in Fig.5a,the layered structure in as-deposited sample is obvious,and the interlayer region was composed of columnar dendrites,fine equiaxed crystals and coarse equiaxed crystals.Moreover,there are large quantitative micropores in the interlayer region,which would affect mechanical performance.After T4 heat treatment(Fig.5b),with the partial dissolution of eutectic structure,the original layered structure characteristics got blurred and cannot be easily identified.The layered structure of deposition after T5 heat treatment(Fig.5c)became more obvious,and the degree of solute segregation is enhanced.After T6 heat treatment(Fig.5d),the layered structure becomes fuzzy because of the solid solution,while the aggregation characteristics of the DPs still reflect the original layer interface.

Fig.3.OM and SEM images with EDS results of WAAM AZ80M alloys:(a)and(b)in AD condition;(c)and(d)in T4 condition;(e)and(f)in T5 condition;(g)and(h)in T6 condition.

Fig.6 is the X-ray diffraction pattern of WAAM AZ80M Mg alloy upon different heat treatments.The main phases are;α-Mg matrix,β-Mg17Al12and a small amount of Al2Y.It can be seen from Fig.6 that the positions of the characteristic peaks were the same,but the biggest difference of the spectra was the peak position(35.9-2θ)of the highest peak ofβ-Mg17Al12phase under different heat treatment conditions.In comparison to the as-deposited(AD)sample slight shift to the lower angles was found for T4 and T6 indicating lattice expansion.However,T5 sample indicated a larger shift to the higher 2θvalue resulted from a lattice contraction ofβ-Mg17Al12phase.There might be several reasons for this difference between T5-treated sample and the others.One might be related to the variation in composition ofβ-phase due to additional solution treatment for T4 and T6 samples.On the other hand,the presence of residual stress can also lead to the contraction of the lattice.More detailed analysis needs to be pursued for determining the main factor[29].

3.2.Mechanical properties

Fig.4.Elements distribution of the WAAM AZ80M alloy obtained by EDS map scanning:(a)as-deposited,(b)T4,(c)T5 and(d)T6 condition.

Fig.5.Microstructure of the interlayer zone:(a)as-deposited,(b)T4,(c)T5 and(d)T6 condition.

Fig.7 shows the microhardness values distribution of the WAAM AZ80M Mg alloy under different heat treatment conditions.The hardness value was 55.47 HV for T4,78.4 HV for T5 condition,66.94 HV for T6,and 62.42 HV for AD condition.In comparison to the hardness value of as-deposited alloy,it decreased by 11% for T4,and increased by 26% and 7% for T5 and T6 heat treatment,respectively.In addition,there were differences in the hardness distribution within the material under different heat treatment conditions.With the increase in the content of the second phases in an alloy,the deformation resistance and the hardness of the material can be effectively improved.The hardness distribution of T4 and T6 was more uniform,while that of T5 was more uneven when compared with that of AD condition.This phenomenon was consistent with the results of SEM.

Fig.6.XRD diffraction patterns of the WAAM AZ80M alloy.

The ultimate tensile strength(UTS)and elongation(EL)results of the WAAM AZ80M Mg alloy under different heat treatment conditions are shown in Fig.8.The tensile properties of AD samples presented anisotropic characteristics.In vertical direction(UTS:224 MPa,EL:13%),the UTS and EL was 64 MPa and 2% lower than those in horizontal direction(UTS:288 MPa,EL:15%),respectively.According to the variations of UTS and EL shown in Fig.8,after different heat treatment,the mechanical performances of the WAAM AZ80M Mg alloy were improved in different aspects.The EL of T4 sample increased by 60%in horizontal direction and increased by 23% in vertical direction than that of AD samples,which means solution treatment can improve the ductility.Compared to the AD samples,the UTS of the T5 sample in horizontal decreased by 6%,and increased by 15%in vertical,but the EL decreased significantly both in the horizontal and vertical directions.Though,the anisotropy after T5 heat treatment seems to be the least pronounced,considering the error bar(the deviation range of strength and plasticity test results in different directions),the effect of T5 heat treatment was not optimal.The UTS and EL of the T6 samples were 292 MPa and 16% in horizontal direction,and 283 MPa and 14%in vertical direction,respectively.Compared with AD state,both strength and plasticity were improved,and the difference between horizontal direction and vertical direction was obviously weakened.The comprehensive performance was better for several heat treatments.It can be concluded that both T4 and T6 heat treatment can improve WAAM AZ80M alloy mechanical performance and reduce anisotropy.

Fig.7.Microhardness distribution of WAAM AZ80M alloys(a)as-deposited,(b)T4,(c)T5 and(d)T6 condition.

Fig.8.Tensile properties of WAAM AZ80M Mg alloy under different treatment conditions

Fig.9.The effect of interlayer defects on tensile strength’s anisotropy.

Fig.10.The side view result of the tensile samples in vertical direction:(a)as-deposited,(b)T4,(c)T5 and(d)T6 condition.

Fig.11.Fracture feature for WAAM AZ80M alloys:(a)as-deposited,(c)T4,(e)T5 and(g)T6 in horizontal direction;(b)as-deposited,(d)T4,(f)T5 and(h)T6 in vertical direction.

However,the mechanical performance improvement of WAAM AZ80M by heat treatment was restricted by the micropores in the interlayer region.The existence of pores may limit the application of WAAM to a great extent,however,it was difficult to avoid the porosity[30],since the WAAM of Mg alloys was based on the traditional welding process.As shown in Fig.9,the effective bearing area along the vertical direction will be significantly reduced due to the interlayer defects.As shown in Fig.5,there were still a lot of porosity defects in the interlayer area of the WAAM AZ80M Mg alloy even if different heat treatments were carried out,which greatly reduced the improvement in mechanical performance of the alloy by heat treatment.The heat treatment can change the microstructure but cannot eliminate the pores formed in the layer by layer deposition process.

The difference of tensile properties in horizontal and in vertical directions of heat-treated WAAM AZ80M Mg alloy was related to its microstructure.It was necessary to reduce the inhomogeneity of the vertical structure as much as possible.T4 treatment reduced the amount and size of eutectic structure and increased plasticity.In T5 heat treatment,the precipitates were preferentially distributed along the dendritic boundaries due to the heredity of the element distribution characteristics of the deposited alloy,and the changes of the amount,shape and distribution of the precipitates were the important factors leading to the strengthening of the alloy.After solution+aging treatment(T6),the alloy elements were more evenly dissolved,and the precipitates were more evenly distributed.

The side view results of the vertically fractured samples are shown in Fig.10.For as-deposited and T5 vertical tensile specimens,the fracture occurred at the boundary between the interlayer region(Fig.10a and c),and the cracks along the eutectic structure were observed around the port(as shown by the arrow).The fractures of T4 and T6 samples occurred on the grain boundary,no obvious cracks were found around the fracture,and the grains around the fracture had been deformed(Fig.10b and d).

Fig.11 shows the fracture morphologies of the WAAM AZ80M magnesium alloys under different conditions and directions.On the fracture surface of the AD-H sample(Fig.11a),there were dimples of uneven size,particles and small secondary cracks at the bottom of the dimple,while the dimples at the fracture surface of the vertical sample(Fig.11b)were significantly less than those of the horizontal sample.After T4 heat treatment,the dimples on the horizontal sample’s fracture(Fig.11c)became uniform and the toughness characteristics were enhanced,while the dimples on the vertical sample fracture(Fig.11d)were relatively shallow and accompanied by a small number of cleavage steps.The fracture of the horizontal sample(Fig.11e)treated with T5 was composed of rough small particles and curved tear edges,and both sides of the tear edges were composed of cleavage steps of different sizes,while the fracture of the vertical sample(Fig.11f)was mainly composed of tearing edges and cleavage steps,and there was a fracture platform,showing the characteristics of brittle fracture.After T6 heat treatment,the dimples on the fracture surfaces of the horizontal and vertical samples(Fig.11g and h)decreased with the tear edges increased.This is because the effective binding area between phase andα-Mg dispersed on the matrix increased,which enhanced the binding force with the matrix and thus increased the strength of the material.

4.Conclusion

In this study,WAAM AZ80M Mg alloy was produced based on GTAW process,and three different kinds of heat treatment methodologies(T4,T5 and T6)were conducted to the WAAM fabricated AZ80M Mg alloy.The microstructure and mechanical properties of as-deposited and post heattreated samples were investigated.The conclusions can be drawn as following.

1.The microstructure of the as-deposited state was mainly equiaxed dendrite,and the second phase was distributed along the interdendritic regions to form a network structure.The average microhardness was 62.4 HV,and the horizontal direction and the vertical direction had tensile asymmetry.

2.T4 heat treatment made the eutectic phase dissolved and eliminated the inhomogeneity of some interlaminar structure,the hardness value decreased to 55.7 HV,and the UTS both in horizontal and vertical decreased but the EL increased significantly.

3.T5 treatment inherited the characteristics of the dendritic structure,and the discontinuous precipitation distributed along the eutectic phases.The average microhardness was 78.4 HV but unevenly distributed.The UTS was improved but EL decreased significantly.

4.T6 treatment formed continuous precipitation in the grains,and effectively improved the microstructure uniformity.The average microhardness was 66.9 HV.Both the UTS and EL in horizontal and vertical direction improved,and the anisotropy was somewhat reduced.

Declaration of Competing Interest

None.

Acknowledgment

This work was supported by the China Scholarship Council[grant numbers:201907000039],the National Key Research and Development Plan of China[grant number 2017YFB0305905].The authors acknowledge the financial support from the 2020 open projects[grant numbers:KLATM202003]of Key laboratory of Advanced Technologies of Materials,Ministry of Education China,Southwest Jiaotong University.

Journal of Magnesium and Alloys2022年7期

Journal of Magnesium and Alloys2022年7期

- Journal of Magnesium and Alloys的其它文章

- Research on deformation mechanism of AZ31 magnesium alloy sheet with non-basal texture during uniaxial tension at room temperature:A visco-plastic self-consistent analysis

- On the deformation behavior of heterogeneous microstructure and its effect on the mechanical properties of die cast AZ91D magnesium alloy

- Computational design of Mg alloys with minimal galvanic corrosion

- Preparation of functional coating on magnesium alloy with hydrophilic polymers and bioactive peptides for improved corrosion resistance and biocompatibility

- Development of open-porosity magnesium foam produced by investment casting

- Development of anti-corrosive coating on AZ31 Mg alloy subjected to plasma electrolytic oxidation at sub-zero temperature