Decontamination of infected plant seeds utilizing atmospheric gliding arc discharge plasma treatment

Chengcheng LIU (劉成成), Jianfeng CUI (崔見鳳), Di ZHANG (張頔),Hongwei TANG(湯紅衛(wèi)),Biao GONG(鞏彪),Shengxuan ZU(祖圣宣) and Chongshan ZHONG (仲崇山)

1 College of Information and Electrical Engineering, China Agricultural University, Beijing 100083,People’s Republic of China

2 College of Horticulture Science and Engineering, Shandong Agricultural University, Tai’an 271018,People’s Republic of China

Abstract In agriculture production,plant health is threatened by pathogens parasitic on seeds;hence,it is necessary to disinfect harvested seeds before germination.In this study, a technique of gliding arc plasma treatment was proposed and investigated.The experiment was conducted to treat Astragalus membranaceus (A.membranaceus) seeds that were artificially infected with Fusarium oxysporum(F.oxysporum).The plasma treatment duration varied from 30 s to 270 s.Direct and indirect treatments were compared to evaluate the inactivation efficiency of the F.oxysporum spores on the surface of seeds.The results indicated that the direct treatment behaved significantly better in disinfection than the indirect way.Meanwhile, experiments of the quantitative assessment of seed germination were also conducted,including the germination rate,the germination potential, and the germination index.The results showed that the inactivation efficiency increased as the plasma treatment time was extended.When the treatment time was 90 s, the inactivation efficiency reached more than 98%.The plasma treatment of 270 s had a complete devitalization of F.oxysporum spores on the surface of the seeds.After the treatment of 30 s and 90 s, the seed germination parameters improved significantly.This study verified the inactivation efficacy of gliding arc discharge plasma under atmospheric pressure.The technique of gliding arc treatment shows advantages of energy saving and adaptation and has the potential to be utilized in industry.

Keywords: gliding arc discharge plasma, Fusarium oxysporum, Astragalus membranaceus seeds, inactivation, seed germination

1.Introduction

Over 90% of the crops on Earth are produced through seeds,which are susceptible to seed-borne diseases.Seed-borne diseases can result in a low germination rate,degrade the vigor of seeds, and even ruin seedlings.Therefore, it is essential to disinfect seeds before sowing [1].

Several techniques have been employed to treat infected seeds, which can be classified into three categories: chemical,biological and physical approaches.Adopting chemical disinfectants to soak seeds can obtain a satisfactory effect;however,toxic waste liquid may cause pollution to the environment [2].The biological methods seem to be environmentally friendly,mainly using beneficial microorganisms and their metabolites to treat seeds.However, they not only require an extended processing time but also appear to be unstable [3].Physical techniques, including high temperature, ultraviolet rays, ultrasonic,and plasma,behave better in repeatability and waste production.Among these techniques,low-temperature(or cold,non-thermal)plasma(LTP),one of the emerging technologies,has advantages as follows: non-thermal treatment that can prevent seeds from thermal damage;precise control;simultaneously disinfecting and enhancing the vigor of seeds, etc.Regarding their potential in agricultural applications, researchers have reported plant seed decontamination using LTP, such as treatment of pepper [4],wheat [5, 6], beans [7] and corn [8].

Contemporarily, LTP has been widely investigated in various agricultural applications.The common types of LTP include dielectric barrier discharge(DBD),corona[9],glow discharge [5], and gliding arc [10, 11].Ultraviolet rays and reactive oxygen and nitrogen species(RONS)can react with the pathogen on the seed coat, disinfecting directly or disrupting propagation capability.Studies using LTP to treat seeds (infect withAspergillus spp.,Penicillium spp.[7],Fusarium oxysporum(F.oxysporum) [12],Aspergillusflavus[13], etc) at atmospheric pressure have shown a good inactivation efficiency.Apart from killing the pathogen,the LTP treatment could also generate an etching effect,modify the surface of the seeds and then change the contact angle of the seed coat.Thus, it might positively influence the germination rate and seed vigor [4, 14].

Gliding arc discharge can create high-density electrons(>1015cm?3), and produce active particles in the gas or liquid phase.Furthermore, the electrochemical conversion efficiency can be up to 75%–80% [15] during production.Consequently, it can transmit a higher proportion of input energy through the electrodes and stimulate the efficiency of chemical reactions [16].Gliding arc plasma has been widely used in industrial fields, such as the degradation of volatile organic compounds [17], air purification, sewage treatment[18],and material surface modification[19].However,to our best knowledge,decontamination of plant seeds using gliding arc plasma has not been explicitly reported.Thus, it is necessary to evaluate gliding arc discharge plasma’s inactivation efficiency in treating the infected seeds.

In this study,Astragalus membranaceus(Fisch.) Bge.var.mongholicus(Bge.)Hsiao (A.membranaceus)seeds andF.oxysporumwere selected as the experimental seeds and pathogen,respectively.Under natural conditions,the seeds ofA.membranaceusare more likely to be infected by theF.oxysporum, which will probably cause root rot.Besides, the plant’s capability to absorb water and nutrients may be weakened, eventually leading to the death of the plant or a reduction in crop yields [20].

Experiments have been conducted to investigate the efficiency of inactivation treatment onF.oxysporumspores on theA.membranaceusseeds surface using gliding arc plasma with ambient air.The observation of the influence on the seed germination parameters was inclusive.

2.Materials and methods

2.1.Experimental configuration

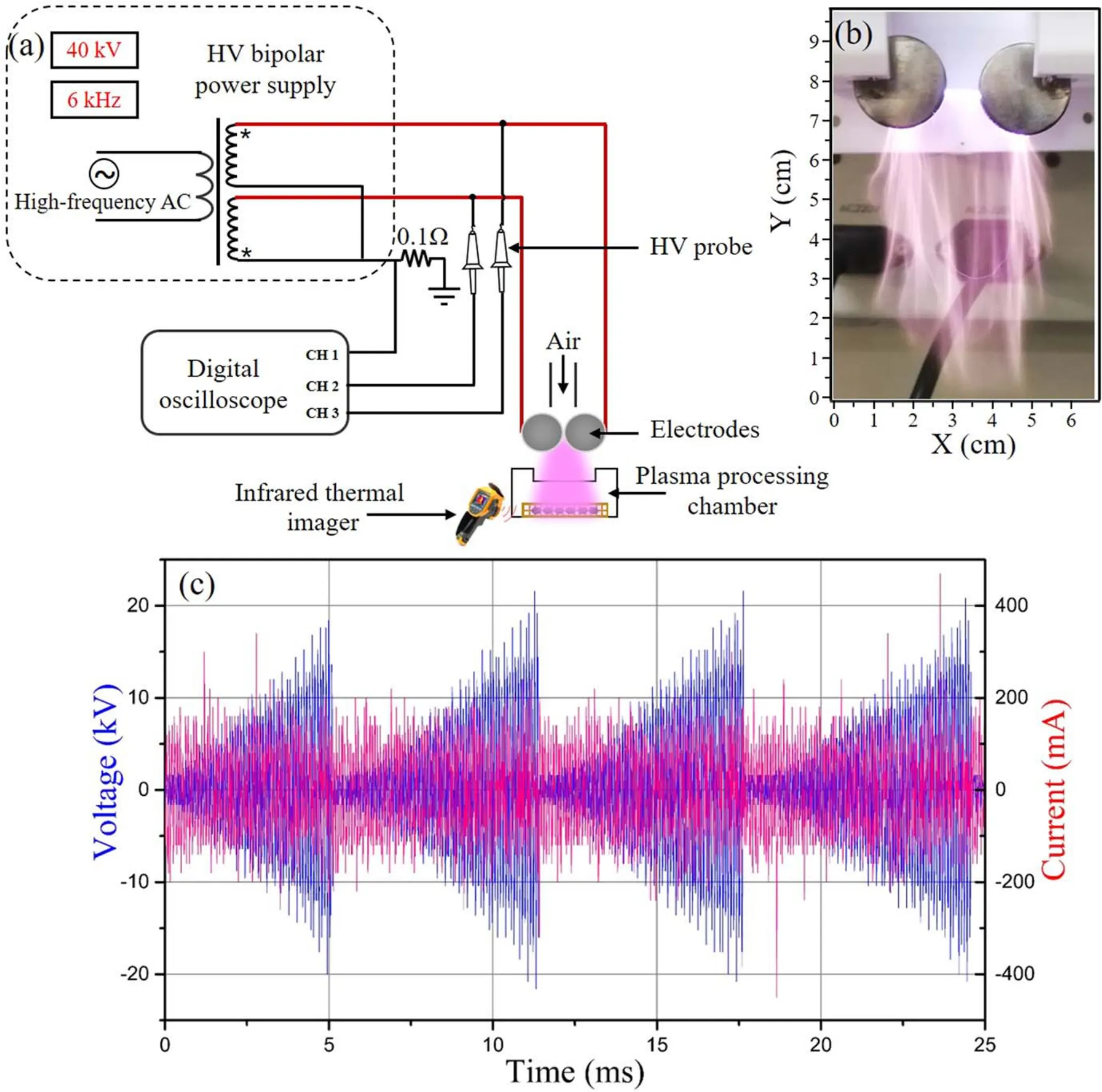

Figure 1 demonstrates the configuration of seed treatment experiments,consisting of four components:air supply,gliding arc discharge plasma reactor,plasma processing chamber,and measurement unit.Ambient air was used as the working gas,which was supplied by a 12 V DC wind-blower with the velocity of the wind at 6.0 m s?1, and the velocity was measured by a digital anemometer (GM8901, Shenzhen Jumaoyuan Science and Technology Co., Ltd China).The plasma reactor consisted of two stainless steel circular electrodes(diameter of 23 mm, and thickness of 2 mm) connected to a high-voltage and high-frequency bipolar power supply(the two output voltages are 180° out of phase).The distance between the two electrodes was 8 mm.The cylinder plasma processing chamber was placed horizontally, of which the top and bottom sides were cut.Cotton cloth placing seeds covered the bottom opening.The plasma was blown from the top opening (figure 1(a)).An oscilloscope (DL850, Yokogawa Co., Ltd Japan) was used to record voltage and current waveforms.The attenuation ratio of the high-voltage probe was 1000:1,which measured the high-voltage input,and the current input was from a noninductive 0.1 Ω resistor.The infrared thermal imager (U5855A, Agilent Technologies, Inc.American)was used to measure the temperature of treated seeds.The power of the plasma reactor was calculated by the formula:

Figure 1.Configuration of gliding arc plasma disinfection treatment of seeds.(a)Experimental setup,(b)photograph of gliding arc discharge,(c) current and voltage waveforms.

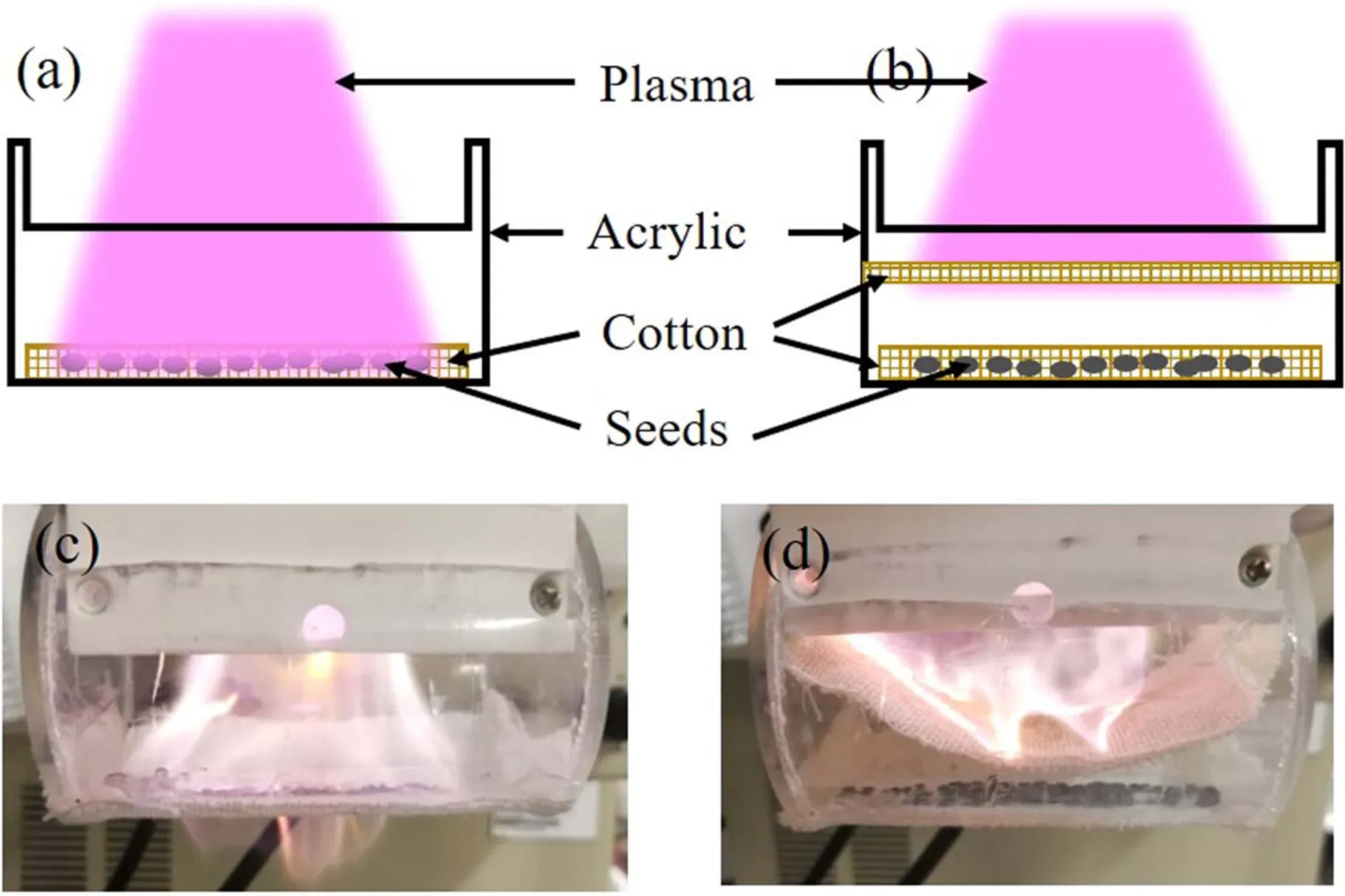

Figure 2.Process of gliding arc plasma treatment seeds.Schematics of (a) direct plasma treatment and (b) indirect plasma treatment, and photographs of (c) direct plasma treatment and (d) indirect plasma treatment.

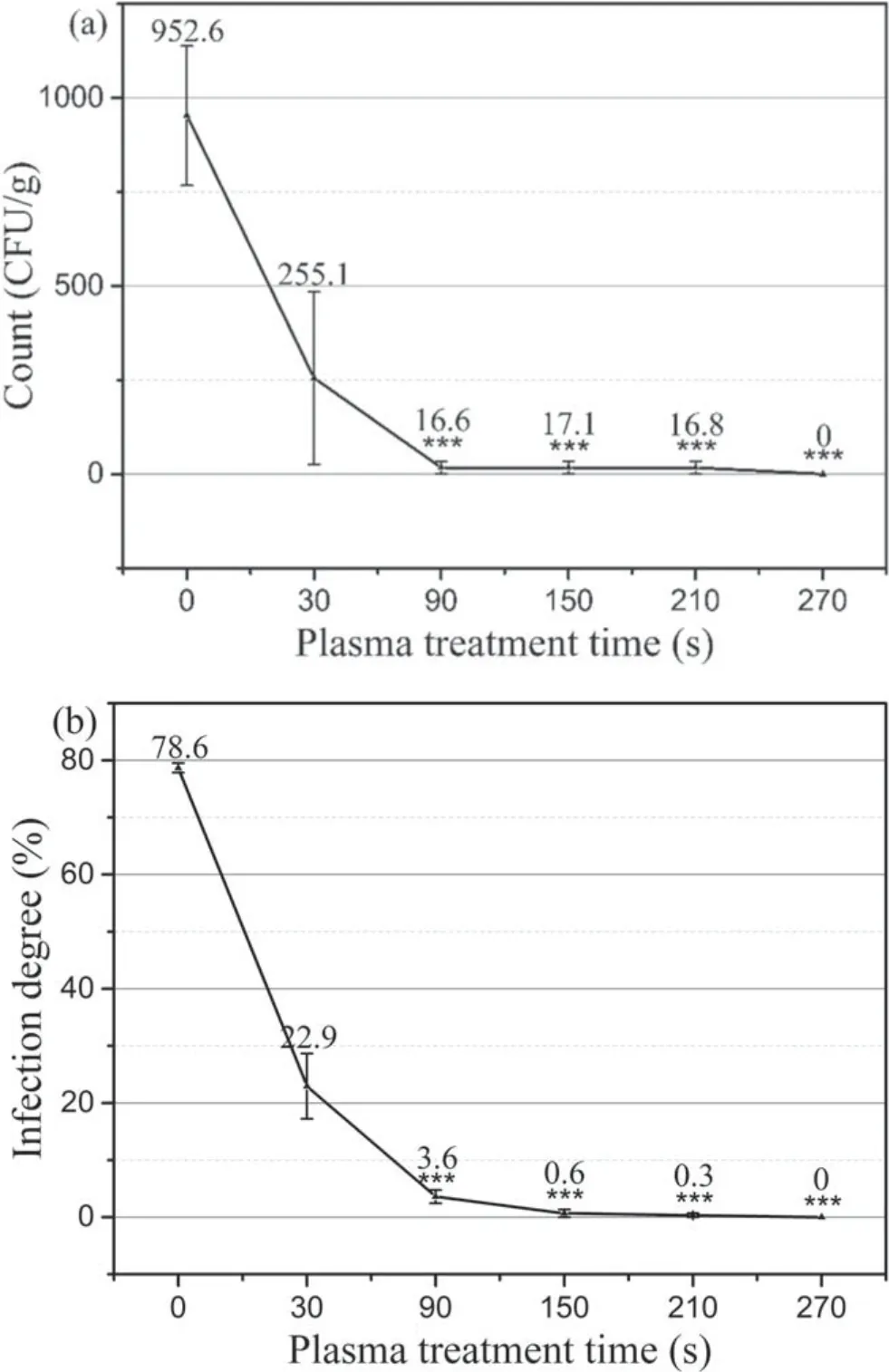

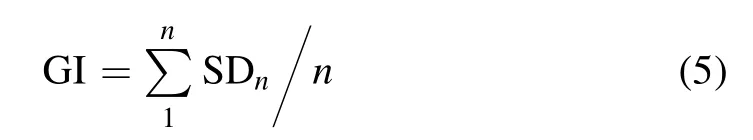

Figure 3.Effect of the different exposure times of gliding arc plasma treatment on artificially infected F.oxysporum on the A.membranaceus seed surfaces and evaluation by different methods: (a) agar plate counting, (b) infection degree.The data in the graph are the average of three repetitions±standard error.A one-way analysis of variance(ANOVA)was used to evaluate the significant discrepancy between treated samples and untreated samples (*P<0.05;**P<0.01; ***P<0.001).

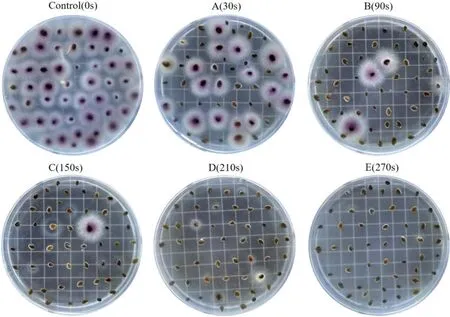

Figure 4.Photographs of seeds inoculated with F.oxysporum and treated with gliding arc plasma for different times and cultivation on the PDA after 3 days.Control (0 s), A (30 s), B (90 s), C (150 s), D (210 s), and E (270 s).

whereu(t) andi(t) are the voltage and current of the reactor,respectively.Due to the randomness of discharge, more than four cycles of the waveforms were sampled and the calculation was listed.The amount of power consumed by the plasma was approximately 270 W.

2.2.Inoculation of the pathogen to seeds

Seeds ofA.mongholicuswere purchased from local seed providers in Inner Mongolia, China.Seeds were filtered for size and fullness.The seeds were put in 10%NaClO solution for 10 min and then rinsed five times with distilled water to exclude the influence of other microorganisms on the experimental results.Since the dry surfaces of seeds were a prerequisite for surface plasma treatment, the seeds were dried under an electric heating blast drying oven for several hours.

F.oxysporumwas used as the target fungal to evaluate the disinfection performance provided by the College of Plant Protection, China Agricultural University.F.oxysporumwas cultured on potato dextrose agar (PDA) in an incubator at 28°C for five days.Several mycelial plugs from the edge of the colony were transferred to 250 ml flasks,which contained potato dextrose broth, and incubated at 28°C on a rotary shaker at a speed of 160 rad/min.After five days, the liquid was passed through two layers of sterile cheesecloth to filter out tiny fragments of hyphae.The microconidia were counted under a microscope at approximately 1×107spores/ml using a hemocytometer.The spore suspension was diluted to the concentration of 1×106spores/ml.The seeds were inoculated with fungal spore suspension in 100 ml centrifuge tubes and incubated at 28 °C on a rotary shaker at a speed of 160 rad/min for 30 min.The seeds were separated from the solution and airdried in a laminar hood overnight.All operations were performed under aseptic conditions.

2.3.Seed treatment with plasma

Fifty infected seeds were placed on the cloth of the processing chamber.To ensure each seed could be treated simultaneously,they were arranged on one layer and along with the shape of the plasma, as shown in figure 2.The distance between the electrode tips and the surface of the seeds was 4.5 cm.

In this study, two treatment methods were compared,demonstrated in figure 2.For the direct plasma treatment(figures 2(a) and (c)), seeds were fully in contact with the gliding arc plasma; as for the indirect treatment, a layer of cotton cloth was placed between the plasma and the seeds(figures 2(b) and (d)), so the plasma could not contact seeds directly, but through the reacted gas.The plasma directly treated the contaminated seeds for 30, 90, 150, 210, and 270 s, respectively.To compare the inactivation efficacy between the direct and indirect methods, both of them were conducted in 150 s.

Seeds were flipped five times at equal intervals to ensure all parts of the seeds could be treated evenly.During each interval,the temperature of the surface of seeds was measured by the infrared thermal imager.The treated seeds were kept at room temperature for 4 h to recover the spores.

2.4.Evaluation of the survival of spores after plasma treatment

The rough surface of the seed coat or the presence of small cracks will hide the fungal spores from exposure,so different exposure times will affect the final inactivation efficiency[13].Two different exposure methods were demonstrated as follows: sections 2.4.1 and 2.4.2.

2.4.1.Agar plate counting method.Treated seeds were put into the normal saline (2 ml, 0.9%) and then shaken on a rotary shaker for 30 min at a frequency of 4 Hz.Dilution ratios were determined according to the level of expected spore population per gram.The 100 μl of dilutions were plated onto the PDA.After 2 days’ cultivation at 28 °C,survival spores were counted in the unit of CFU/g(counts of colony-forming units per gram).

2.4.2.Infection degree method.Fifty treated seeds were placed on the surface of the PDA.After three days’cultivation at 28 °C, each seed was categorized into five classes (from 0 to 5) according to the degree of infection:class 0 represented the absence of fungal; in contrast, class 5 denoted that the fungus colony area was five times larger than the area of seeds.The infection degree (ID, %) [21] is calculated by the equation:

wherenis the number of seeds categorized into the class,andvis the fungal infestation class(from 0 to 5).NandVare the total numbers of assessed seeds (50) and the highest infestation level (5), respectively.

2.5.Seed germination

The experiment was performed to observe whether the disinfection treatment would affect the germination or vigor of seeds.According to the standard of Regulations for Crop Seed Inspection (GB/T 3543.4-1995, China Quality and Standards publishing & Media Co., Ltd China), in each experimental group, 50 treated seeds were placed in a 12 cm×12 cm germinating box with two layers of wet germinating paper, and then the seeds were incubated in a 25°C constant temperature and humidity incubator (60%–70% moisture) without light.Distilled water was added in time to keep the germinating paper’s moisture.When the seed bud pierced the seed coat and reached more than 1 mm in length, this seed was counted as one germination.The germinated seeds were counted for 7 days from the beginning of the incubation.The germination rate (GR, %) of seeds is calculated by the equation:

where SG7is the number of germinated seeds on the seventh day, and ST is the total number of seeds.The germination potential (GP, %) can be calculated by equation (4):

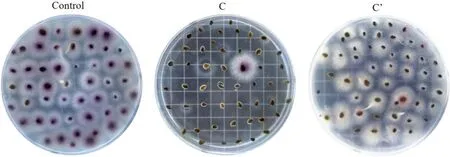

where SG4is the number of germinated seeds on the fourth day, and the germination index (GI) is calculated using the equation:

where SDnis the number of seeds germinated on dayn.Each germination experiment after plasma treatment was repeated five times.

2.6.Statistical analysis

The data were presented as the mean±standard error (SE).A one-way analysis of variance (ANOVA) was used to evaluate the significant discrepancy between treated samples and untreated samples; differences were considered significant whenPwas less than 0.05.

3.Results

3.1.Inactivation effect

Both the agar plate counting method (2.4.1) and the infection degree method(2.4.2)were compared to evaluate the inactivation efficiency of theF.oxysporumspores on the surfaces of seeds.

Figure 3(a) demonstrates that the gliding arc plasma treatment significantly reduced the number of colonies ofF.oxysporumattached to the seeds.Compared to the untreated group (mean=9.53×102CFU/g), more than 98% ofF.oxysporumon the surface of seeds were killed by the direct gliding arc plasma treatment within 90 s.

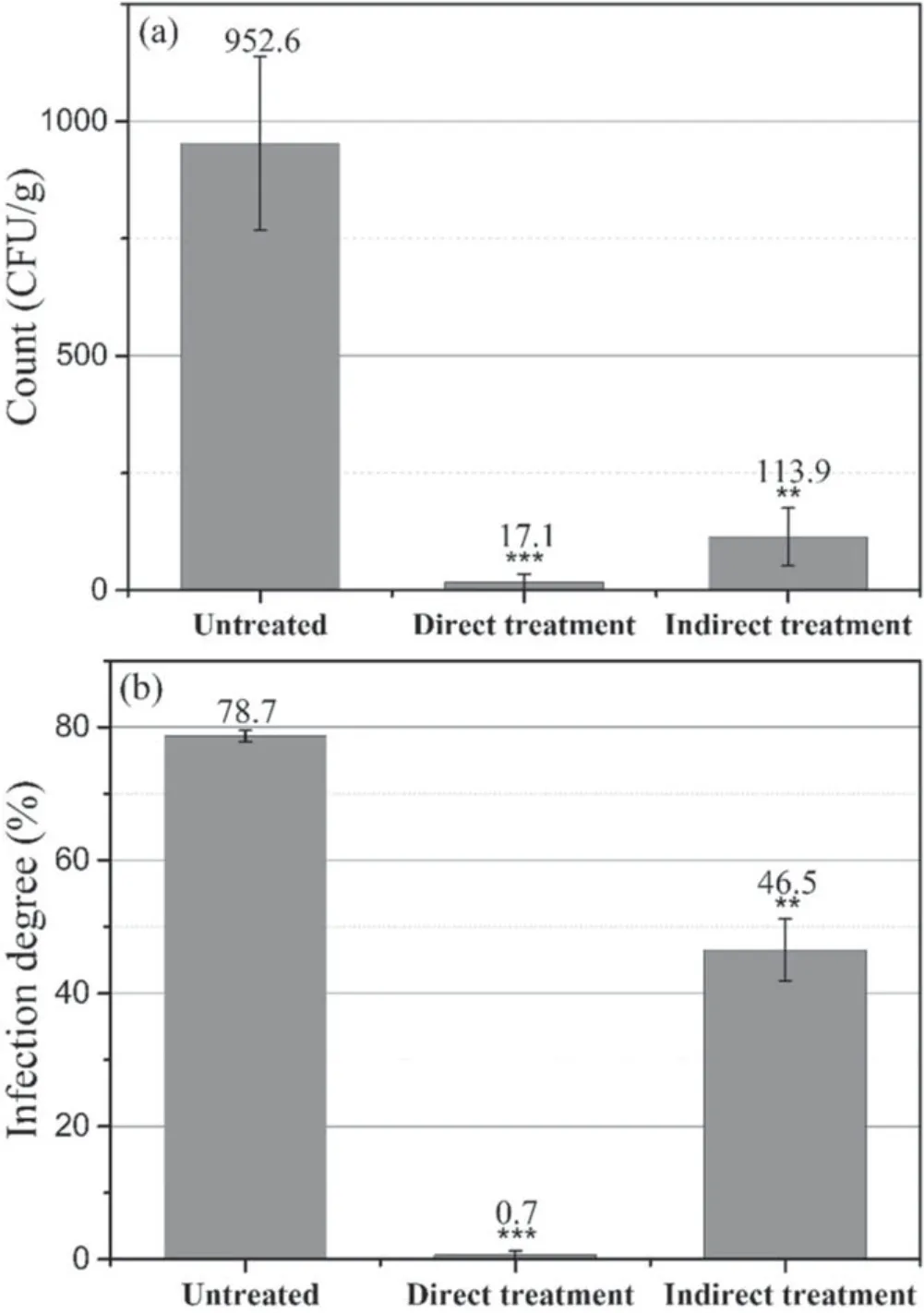

It was found that the infection degree method(figure 3(b)) also obtained a similar result to the conclusion revealed by the agar plate counting method.Figure 4 displayed the infection images of untreated and treated seeds(from 30 s to 270 s).The infection degree of untreated seeds was determined to be 78.67% and significantly reduced to 3.60% after treatment of 90 s, and the infection degree was 0% after 270 s treatment.

3.2.Influence of plasma treatment method on inactivation effect

Figures 5 and 6 revealed the remarkable difference in inactivation efficiency between the direct and indirect treatment methods.The inactivation effect of direct plasma treatment was significantly higher than that of indirect plasma treatment.When treating 150 s directly, the agar plate method’s inactivation efficiency was 98.3%, while the inactivation efficiency was only 55.4% for the indirect plasma treatment.The infection degree method shows that direct plasma treatment was 0.7%,a 45.8%lower infection degree than indirect plasma treatment (46.5%).

Figure 5.Effect of the same exposure times (150 s) of gliding arc plasma different treatment methods on artificially infected F.oxysporum on the A.membranaceus seeds surface and evaluation by different methods: (a) agar plate counting; (b) infection degree.The data in the graph are the average of three repetitions±standard error.A one-way ANOVA was used to evaluate the significant discrepancy between treated samples and untreated sample(*P<0.05; **P<0.01; ***P<0.001).

3.3.Temperature of the seed surface

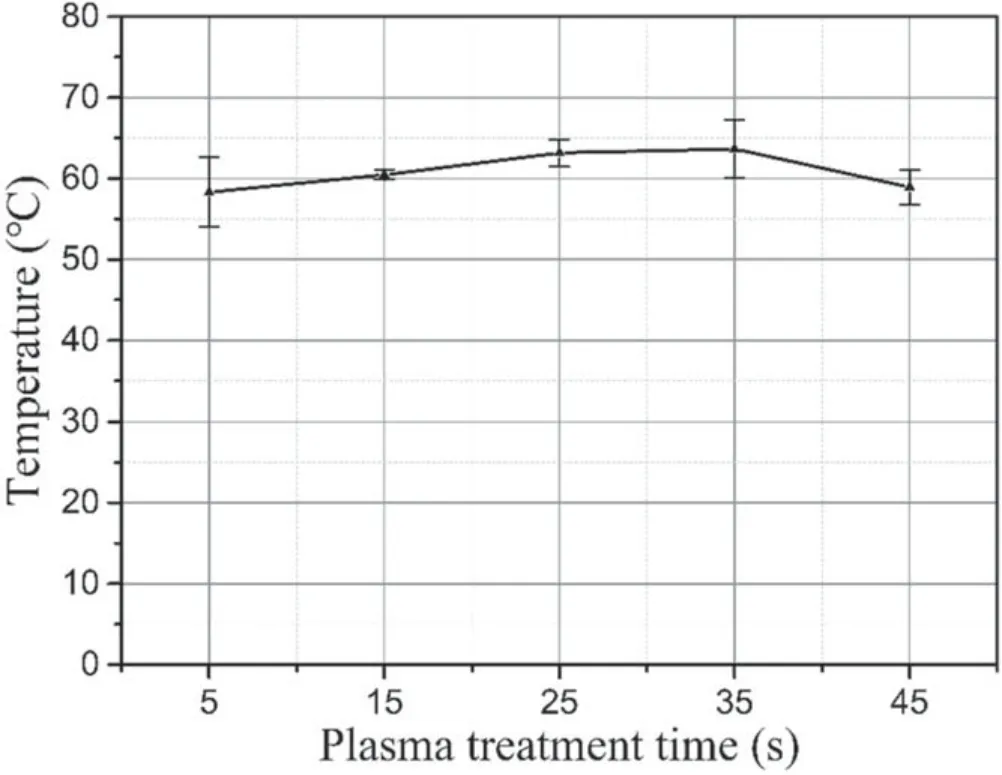

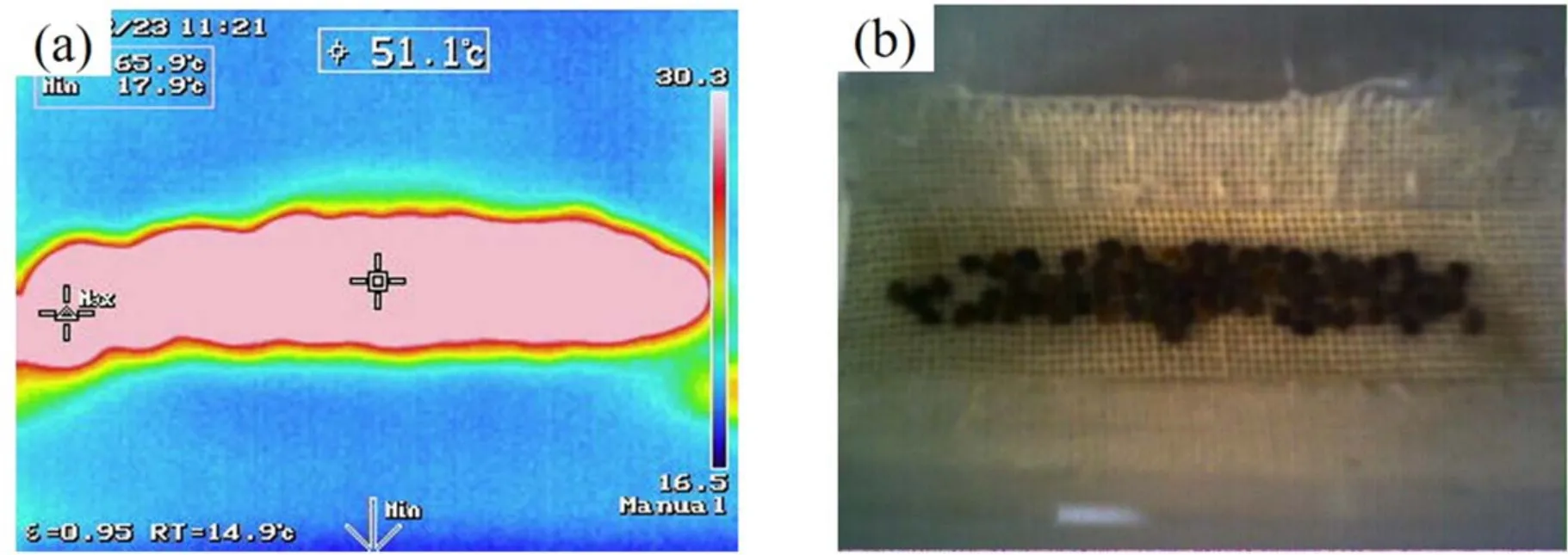

Since seeds were flipped five times by a medicine spoon with an equal interval (10 s) in each experiment during the plasma treatment,the surface temperature of seeds could be restored to room temperature (20 °C) before the continuous processing.Figure 7 showed the maximum temperature rise measured by the infrared thermal imager after each treatment.It indicated that there were no significant differences between each measurement.The surface temperature of seeds increased from room temperature to 60 °C after plasma treatment of 15 s, and the maximum temperature was 63 °C at the 35th second.During the treatment process, the maximum temperature was maintained in the range of 57 °C–63 °C.It indicated that the temperature on the surface of seeds would not rise as duration increased but tended to thermal equilibration.The photos taken by the infrared thermal imager are shown in figure 8.

Figure 6.Photographs of seeds inoculated with F.oxysporum and treated with direct and indirect plasma for 150 s and cultivation on the PDA after 3 days.Control (0 s), C (direct plasma treatment), C’ (indirect plasma treatment).

Figure 7.Maximum temperature of the seed surface.

Figure 8.Infrared image of seed surface after gliding arc plasma treatment of 45 s.(a) Infrared image, (b) seeds after each treatment.

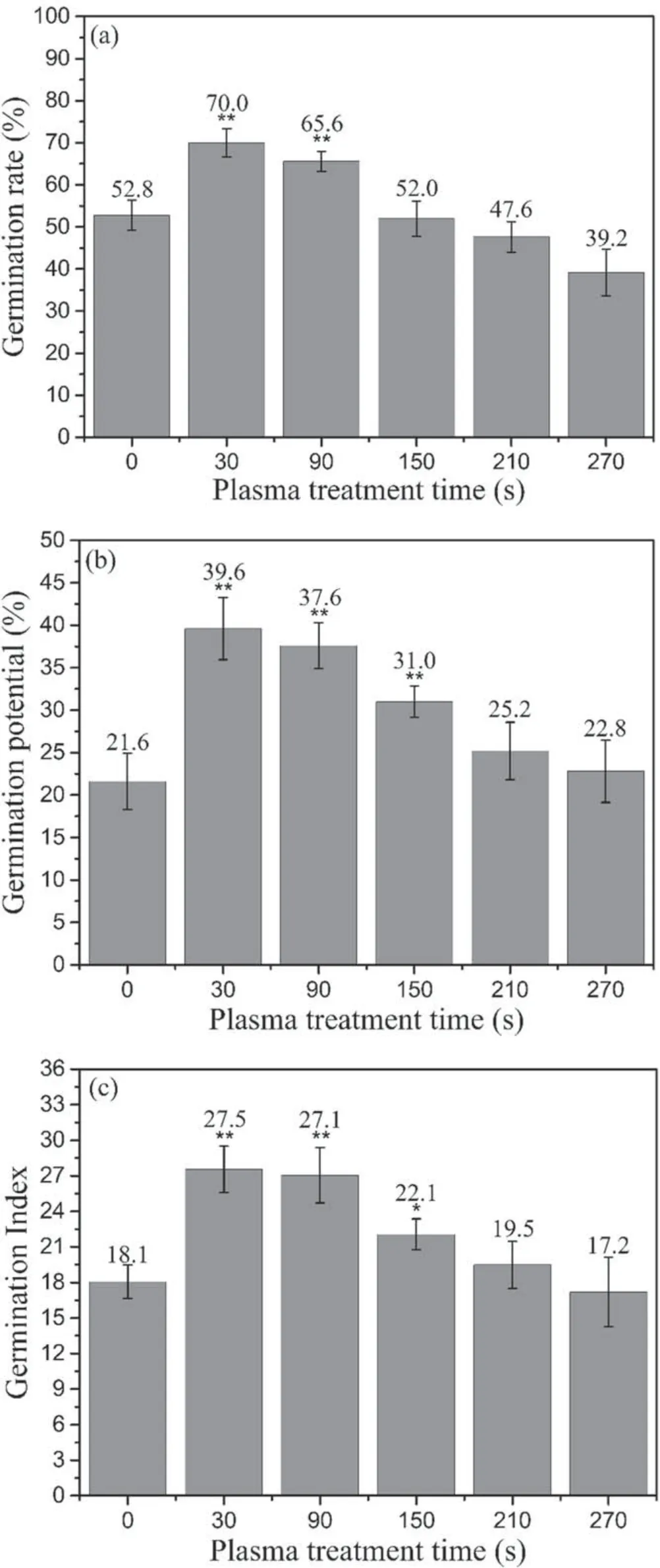

Figure 9.Results of the quantitative assessment of seed germination parameters after treatment with gliding arc plasma at different exposure times.(a) Germination rate, (b) germination potential,(c) germination index.The data in the graph are the average of five repetitions ± standard error.A one-way ANOVA was used to evaluate the significant discrepancy between treated samples and untreated samples (*P<0.05; **P<0.01; ***P<0.001).

3.4.Quantitative assessment of seed germination parameters

The effect of treatment duration on the quantitative assessment of seed germination parameters ofA.membranaceusis shown in figure 9.Compared with the control group, the increase of treatment time created both positive and negative effects on the germination index parameters.The germination rates from 30 s and 90 s treated seeds were 70.0%and 65.2%, respectively, which were 17.2% and 12.8%,respectively, higher than that of the control (52.8%); however, the germination rate tended to decrease slightly from 150 s.For all treatments, the germination potential was enhanced to some degree.The germination index percentages of 30 s, 90 s, and 150 s were 27.5, 27.1, and 22.1,respectively, which were significantly improved by 52.5%,49.8%, and 22.1%, respectively, higher than that of the control.The maximum germination potential, germination rate and germination index were all obtained from the treatment of 30 s.

4.Discussion

4.1.Comparing efficacy with the chemical technique

This work revealed that gliding arc plasma could inactivate more than 98% ofF.oxysporumspores on the surface ofA.membranaceusseeds within 90 s and obtained 100% growth inhibition of spores after the 270 s plasma process.It indicates that the gliding arc plasma technique shows its potential in removal of most of the pathogens from the surface of seeds within a few minutes.Its efficacy can be comparable with conventional chemical processing; for instance, the disinfection efficiency of microorganisms on the surface ofA.membranaceusseeds is about 90% [22] by the chemical disinfectant.

4.2.Factor of treatment duration

Some studies had also employed cold plasma to treat fungiinfected maize by diffuse coplanar surface barrier discharge plasma [23], broccoli by corona discharge plasma jet [9] and wheat by DBD plasma [7], which revealed that complete devitalization was consistent with a sufficiently long processing time.However, the prolonged exposure time could damage the seeds and weaken their germination [23].Some researchers have proven this possibility.For example, ?eráet alobserved a positive influence of diffuse coplanar surface barrier discharge plasma treatment on germination and early growth of seed germination in the process duration of 5 s to 10 s with an optimum at 10 s; on the other hand, they found significantly inhibited germination with increased exposure of seeds to plasma for 60 s[16].Consequently,it is important to determine the appropriate treatment duration and consider aspects as follows.

(1) The inactivation efficacy could depend on species of pathogens; therefore, the requirement of treatment duration could vary with pathogens.(2) The disinfection treatment should not damage the seeds.In this study, figure 9 shows that a duration less than 150 s created almost no negative effect on the quantitative assessment of seed germination parameters.In contrast, parameters were improved to some degree.It is noted that it is necessary to ensure whether plasma disinfection will not affect the seedling in further experiments.

4.3.Key roles of the disinfection by gliding arc plasma

Temperature plays an important role in affecting biological activity.It is reported that the spores ofF.oxysporumwill lose the ability to reproduce when the temperature is lower than 5°C or higher than 45°C[24],and the vitality ofF.oxysporumspores may be lethal when the temperature is above 60°C[25].Besides,the warm water of 60°C has been used as a technique to break the dormancy ofA.membranaceusseeds[26].In this study, the maximum temperature of treated seeds was maintained in the range of 57 °C–63 °C (figure 7).Hence, the surface temperature of seeds treated by gliding arc plasma will be of great benefit to inhibiting the activity of pathogens and contributing to the germination of seeds.

In the experiments using the indirect treatment(figures 2(a)and(c)),seeds were blown by the gas ejected from the gliding arc discharge reactor.It is well known that the gas is rich in RONS (e.g., NXOY, H2O2, O3, ·OH) [27], which are generally regarded as the active substances for disinfection.The shortlived reactive species (·OH and1O2) and long-lived reactive species (H2O2and O3) can effectively inactivate cells mainly through eroding the surfaces of microbial cells and causing oxidative damage to intracellular macromolecules, such as membrane lipids, proteins, and DNA [28, 29].To our disappointment, the gaseous RONS generated by gliding arc plasma could not function well as direct treatment when treated indirectly in terms of inactivation efficiency (figure 5).When treated directly,seeds were immersed in the gliding arc plasma,which contained high-energy electrons, long-lived and shortlived gaseous active substances, and radiated ultraviolet rays[27].Meanwhile, the direct treatment had an etching effect on the seed coats.It can be speculated that, during indirect treatment, the partition between seeds and gliding arc plasma had obstructed a far too large proportion of active substance particles engaged in disinfection.Hence,it finally resulted in worse behavior in pathogen inactivation.Moreover, the shadow function of partition also perhaps made contributions to the reduced radiation of ultraviolet rays and high-energy electrons,which affected the inactivation effect in a roundabout way,and the temperature of indirect treatment(29 °C–34°C)was lower than that of direct treatment(57°C–63°C),which was also an influencing factor that cannot be ignored.Additionally, germination experiments revealed that the direct treatment could enhance the germination of seeds with appropriate treatment duration (figure 9).

4.4.Advantages and prospect of seed decontamination using gliding arc plasma

In previous studies, seeds were mostly disinfected by DBD plasma; however, two weaknesses have impeded its application in the industry: (1) after continuous working for a long time,the temperature rise of the electrodes will be too serious to be ignored,which will not only damage seeds in the reactor but also require the existence of a cooling system which brings up the total cost;(2)DBD plasma is sensitive to many factors (e.g., distance between the electrodes, thickness of dielectric barrier,characteristics of seeds);hence,it cannot be compatible with various work circumstances that vary with the breeds of seeds to be treated.

Fortunately,gliding arc plasma features two advantages:(1) seeds can avoid being damaged by the temperature rise of the electrodes because of the gap between electrodes and seeds; and (2) the plasma flame is hardly affected by seeds during the treatment.Consequently, gliding arc plasma treatment shows good adaptability to different kinds of seeds.

Furthermore,gliding arc plasma decontamination possesses lower power consumption.To illustrate this,it is calculated that the 90 s treatment of 50 infectedA.membranaceusseeds(~0.4 g), which possessed an inactivation efficiency of over 98%, only consumed 6.75×10?3kWh (1.125×10?4kWh per seed).According to China’s agricultural electricity rate(~0.09 $/kWh), each seed costs approximately $1.05×10?5,which is equivalent to $2.27 per Chinese Mu (~667 m3, and 1.5 kg seeds).For seeds that are of great value (e.g., tomato),this technique will become much more economical.

5.Conclusion

The decontamination of seeds utilizing gliding arc plasma has been proposed and investigated in this work.The experiments revealed thatF.oxysporumcould be effectively inactive on the surface ofA.membranaceusseeds by direct treatment of gliding arc plasma.Within 90 s, the inactivation efficiency could reach 98%; meanwhile, the temperature rise of seeds tended to thermal equilibration and lower than 63 °C.The result of germination experiments demonstrated that the seed quality would not be affected when properly treated by plasma.On the contrary,the treatment could also significantly increase the quantitative assessment of seed germination parameters.Compared with DBD plasma treatment of seeds,gliding arc plasma could easily implement control of seed temperature to remain within the upper limit.Meanwhile, it could be more adaptive to treat different kinds of seeds.Additionally, this technique has been proven economical.Finally, this work indicated that the decontaminating technique of gliding arc plasma for seeds shows good potential in industrial-scale applications in the future.

Plasma Science and Technology2021年10期

Plasma Science and Technology2021年10期

- Plasma Science and Technology的其它文章

- Special issue on selected papers from CEPC 2020

- Surface treatment of titanium dioxide nanopowder using rotary electrode dielectric barrier discharge reactor

- Application study on plasma ignition in aeroengine strut–cavity–injector integrated afterburner

- Microanalysis of a ductile iron by microchip laser-induced breakdown spectroscopy

- Study on water treatment effect of dispersion discharge plasma based on flowing water film electrode

- The regulation of memory effect and its influence on discharge properties of a dielectric barrier discharge driven by bipolar pulse at atmospheric-pressure nitrogen